Why Cleaning Your Web Clears a Path to More Profitable Converting

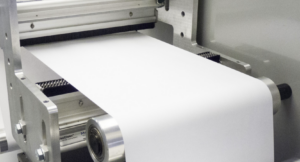

A moving web acts like a magnet for airborne contaminants. Once contaminants are introduced they can become trapped by static charges and the air boundary layer. These contaminants can lead to product defects and increased downtime,which leads to lower profits.

Web cleaning systems like the ones provided by Meech International are becoming increasingly more important.

Meech International is one of the world’s leading manufacturers of static control, compressed air technology and web cleaning systems. Keith Dotray, Territory Manager for Meech, spoke to us on what causes your web to act like a “dirt magnet,” as well as the technologies that can keep it clean.

How do contaminants enter the web process?

Factory floors have become increasingly cleaner through the years, but that doesn’t mean contaminants don’t find their way to the web. According to Dotray, the contaminants come from a variety of sources:

Contamination on the material from the supplier. The material shipped to you from a vendor may have picked up dirt in their own facility.

Debris generated from rotary die cutting or slitting. Any converting process will cause airborne debris.

Electrostatic attraction. Static charges on the web will attract contaminants present in the environment.

Flaking from a material that’s being applied. Dotray noted that in lithium ion battery applications, there may be some flaking from the battery coating.

These contaminants can lead to a host of problems, including:

- Poor quality output: Contamination and imperfections are particularly troublesome to pharmaceutical and food packaging applications.

- Increased downtime: Presses need to be shut down and maintained whenever a web becomes contaminated.

- Less profitable production: Contamination leads to more product rejects.

Naturally, all of these result in unhappy customers and less repeat business. So how can converters literally clean up their act?

Three critical tasks required for effective cleaning

Meech breaks down the web cleaning process into three critical areas. If the web cleaning system fails to perform any of these tasks, effective cleaning won’t occur.

1. Neutralize the Static Charge

Web surfaces typically have a static charge, which is generated by separation (such as when the web is unwound) or friction (when the web travels over non-conductive nip rollers.)

The static charge will trap and hold contamination already present on the web to the surface, and pull ambient airborne contamination to the web. The static charge must be removed; Meech web cleaning systems use ionizing bars to neutralize the charge before and after cleaning, regardless of polarity.

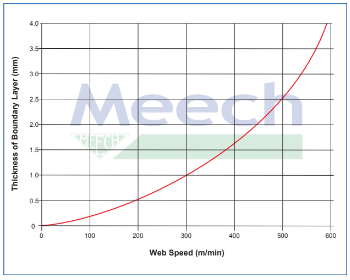

2. Break the Boundary Layer

A boundary layer of air exists on all moving webs. It is formed by ambient air that is dragged along by the moving web. The slower the web moves, the thinner the boundary layer. Conversely, a faster moving web will have a thicker boundary layer.

Contamination becomes trapped on the surface of the web by the boundary layer, or it’s held in the layer itself. The layer needs to be broken, through methods like a positive air knife.

3. Remove and Trap Contamination

Once the boundary layer is broken and the static charge neutralized, the contaminant needs to be removed. The methodology each web cleaning system uses is based on the application.

For example, a paper converting line with typically larger-sized contamination will require a system that’s different from an aluminum electrode web for battery cell production, which has fewer contaminants of a much smaller size.

Meech provides two different types of cleaning technologies:

Non-Contact: Used in cleaning delicate surfaces where physical contact may cause an issue to the surface quality and finish.

Meech’s CyClean™, which provides non-contact…

Meech’s CyClean-R™, web is supported by customers roller for low tension applications.

Contact: Used in applications where contact with the web is not a concern.

VacClean™ contact cleaner is used for fibrous materials, paper, and recycled paper webs.

The systems may vary from vacuum filtration systems to consumable adhesive rolls, which traps contaminants on its surface.

A system will be selected based on customer requirements:

- What is the contamination that needs to be removed?

- Single or double-sided cleaning: Do one or both sides of the material need cleaning?

- Web width: Minimum and maximum web widths passing through the cleaner?

- Web tension: Knowing the minimum and maximum web tension is critical to determine the system best suited for the application.

- Available space and accessibility: How accessible will the system be for your operators.

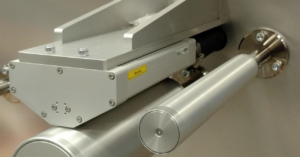

New for the Battery Manufacturing Marketing: The RoClean™-C

The RoClean-C, is our newest contact web cleaner designed specifically for the battery manufacturing market. It solves the problem of removing larger flakes of coating material which may be present.

After the web is neutralized a rotary brush spinning opposite the web direction removes the contaminants. A secondary ionizer neutralizes the outgoing web. Positive and negative airflow in the RoClean-C head is precisely balanced and contamination is collected in our Air Handling Unit.

Does everyone need a clean web?

The need-basis for a web cleaning system falls into the “it depends” category, where you have to evaluate the risk of potential contamination versus the reward of not dealing with it in the first place.

“It really comes down to the quality,” Dotray said. “If you’re running materials that are being coated, laminated or printed, you don’t want any contamination.” He noted food packaging and medical devices also fall within this category.

Speed is also a factor, as downtime from contaminants can affect throughput and the amount of time spent with changeover. Dotray also points out that you shouldn’t overlook the operational impact contaminants can have on your team.

“You want the operator to spend time on productivity, not wasting time on contamination,” Dotray.

If you’re ready to clean up your act, and improve your throughput and efficiency in the process, visit Meech International.

Next Post

MD&M East 2023

Previous Post

Foam Expo North America 2023