Yes, Electronic Sensors Can Do THAT

Much like the latest iPhone, today’s industrial electronic sensors are advancing technologically at an incredible pace. Most people’s perception of sensors is grounded in the past. You may think of them as a crude product for the detection of a registration mark on a web.

Those capabilities remain, sure, but the advancements electronic sensors have made for the converting, packaging and web-related industries has been nothing short of jaw-dropping. We reached out to Todd Spanier of Automation Sensors, Inc. for insights into this exciting, electronic evolution.

How Have Electronic Sensors Advanced?

Spanier notes that the big leaps in electronic sensor technology have occurred largely under the radar.

“People aren’t aware that there are sensors that just weren’t around a few years ago,” he said. Today’s sensors are delivering the speed and repeatability you need to get excellent production, without the cost and training required of a more elaborate system.

In this in-depth interview, Spanier details some of the remarkable advancements. Listen in, and then read on.

The Key Performance Metrics for Electronic Sensors

The best way to describe some of the innovation in electronic sensors is to put it within the context of performance metrics for sensing technology. We’ve described three key performance metrics, and provided examples of how sensors are pushing the envelope in each case:

Repeatability

Repeatability is a measure of the maximum variance in the operating distance that can be experienced in successive operations of a sensor under specified operating conditions.

Let’s apply that engineering-speak to the following example: If you want to detect the leading edge of a hole cut in a web, and there is a one-inch gap from hole to hole, a sensor will detect the deviation in that gap length.

As Todd Spanier explains, in the one-inch scenario mentioned above, sensors have become extremely accurate. “A little $200 sensor can now detect a deviation of .0006 of an inch,” he said.

Resolution

Resolution is the smallest possible change in a target feature that a sensor will detect. This is usually specified in reference to a physical distance, but it’s also a function of color, contrast, density, translucency, etc. A higher resolution sensor will detect smaller changes in these factors.

As an example of resolution, Spanier cites infrared sensors that are designed specifically for picking up water-based components like hydrogel. “It might have required a very elaborate system in the past,” he said. “Now we can use reasonably priced infrared sensors to pick up miniscule amounts.”

Response Time

Response time is defined as being the duration of time required for the interface to trigger an output. The faster the sensor, the more accurate or repeatable your registration should be. Timing error becomes less of a factor with high speed sensors.

Until fairly recently, many industrial sensors had response times of one millisecond (ms) or more. If you took a registration sensor with a 1 ms response time and applied it to web feature traveling at 100 ft per minute, the registration error could be up to .020.” Many new sensors are 100 times faster than the previous generation, thus the registration error on the same traveling web would only be .0002.”

The Best Sensing System is Only as Strong as its Weakest Link

As Spanier notes, “The best sensing system (and thus your product registration or inspection) is only as strong as the weakest link.” All these performance attributes must work together.

For example, an extremely fast and repeatable sensor is useless if it does not have the resolution to accurately detect a target. But even then, an extremely high resolution sensor is also useless if it takes a week to make a decision.

Whatever system you choose, none of these three performance metrics described can be discounted, otherwise the output as a whole may be compromised.

When Do You Need a Sensor Versus a Vision System?

We’ve blogged about vision systems in the past. As Spanier notes, both have a place. While these factors might differ per usage scenario, here are some general guidelines to consider:

Cost: Many sensors can meet the performance attributes described above for only $200-300 per unit.

Training: If you don’t have the resources to train your operators on a more elaborate vision system, sensors have proven to be user-friendly.

Quick changeover: If you’re a contractor running many jobs, your changeover times may restrict you from a more complicated vision system.

And Vice Versa…When Do You Need a Vision System Vs a Sensor?

Vision systems are ideal for more specialized jobs, and are especially applicable to the medical and pharmaceutical industries, where tight tolerances and regulations come into play. Here are some general factors to consider:

Multiple features: If your production run requires multiple features to be considered simultaneously, vision sensors make sense. For example, if you have 15 lanes on a web and the run requires multiple features, it will be difficult to find the space for that many sensors, much less make the changeover efficient.

Mechanical control: If your web is drifting back and forth instead of running straight, vision systems make sense. When your die-cutting machine manufacturer spends a lot of time on web steering technology, then drift won’t be an issue.

Resources: If your budget allows for a well-trained workforce and the quality controls to ensure you’re using a vision system correctly, then it might be the right choice. Pharmaceutical or medical equipment contracts generally provide for more resources to meet more stringent regulations.

Types of Industrial Electronic Sensors

We’ve detailed some big picture considerations with electronic sensors. Now let’s take a closer look at just a few types of sensors that can be applied to converting, packaging and web-based production.

Ultrasonic Sensors

An ultrasonic sensor utilizes high frequency sound waves to detect or measure an object. These sensors have the advantage of being immune to changes in color, reflectivity, transparency, and a great deal of environmental contamination.

Both switch and analog output versions are available and they can be used in proximity, background (retroreflective), or through beam configurations.

Photoelectric / Laser Sensors

Photoelectric and laser sensors utilize light energy to detect, identify, or measure an object. This technology is the most widely used for industrial machine automation, product inspection, and material handling applications.

Many models are capable of detecting slight differences in color, contrast, reflectivity and distance. Both switch and analog output versions are available and they can be used in light diffused (proximity), background (retroreflective), or through beam configurations.

Fiber Optics

Fiber optic light guides are efficient conduits for carrying light energy from photoelectric sensors into areas where physical space is limited. They can be used in light diffused (proximity) or through beam configurations.

Capacitive Sensors

Capacitive sensors detect objects by noting a change in the dielectric coefficient or density of a target. Useful applications include liquid level monitoring and plastic or food product detection. Slot or fork style versions are used for detection of clear labels, splices, web voids and splice detection.

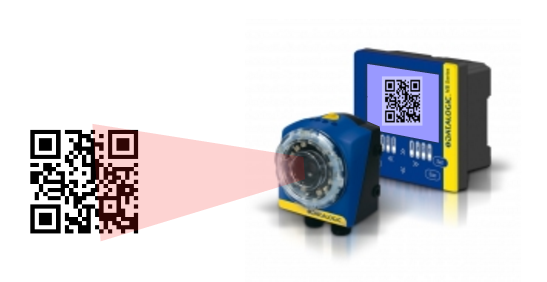

Vision Systems

Vision systems are utilized to inspect and measure products in a much wider “field of view” than a traditional photoelectric sensor. A vision sensor is a slower and lower resolution version of a full fledged vision system. Lighting is critical to any vision sensing solution.

Next Steps: Evaluate Your Specs and Your Budget

The one constant about this business is that every job is different. With so many factors to consider — tolerances, changeover, regulations — each production run may require different approaches.

While the multiple technologies in the marketplace can make your head spin, think of all these options as an opportunity to expand your customer base.

As Spanier notes, with a small investment and very little operator training, you can achieve sensor detection formerly only in the purview of vision systems. Where once you couldn’t, now you can. Electronic sensors open up the door for all types of possibilities, so use them to get your foot in the door with new customers.

OVERCOME YOUR BIGGEST CONVERTING AND PACKAGING CHALLENGES

Published on Nov 07 2016

Categories: Delta ModTech Blog, Innovation

Previous Post

Should You Automate Corrections in Real Time?