4 Ways Scrap Can Reduce OEE

Let’s start with a simple fact: Waste is a way of life in the converting business. No matter what you’re cutting with your rotary die, there will be sections of the part that will be waste. Be it a hole or an odd-shaped piece, that waste won’t stay with the web.

Scrap removal is the process of disposing of those slugs and scraps. It can either be done manually or the process can be automated with a part or add-on to your rotary die machine. And it can have a profound impact on your overall equipment effectiveness (OEE).

Efficiency Impact: How Scrap Reduces Your OEE

Improving OEE in your manufacturing equipment is always the goal. As we all know, OEE, or overall equipment effectiveness, is the percentage of manufacturing time in which a machine is truly productive.

Achieving an OEE score of 100% means you are manufacturing only quality parts, as fast as possible, with no downtime. Scrap and slugs pose a threat to all three of those areas, as they can cause:

Tooling and Press Damage

When scrap accumulates inside a die cavity, pressure builds rapidly, resulting in blade fractures and complete blade failure. Loss of production time and additional tool repair costs can result.

Scrapped Parts

If scrap gets between the anvil and the contact surface of the rotary die, such as the die bearers, the tool will not be fully-seated against the anvil, resulting in an uncut part. This increases production costs, especially when converting expensive materials.

Increased Press Clean-Up Time

Without effective slug removal, your press operators must spend additional time cleaning the equipment. Often when scrap gets into the gear train and other critical press areas, immediate cleaning is required, thus increasing production time and reducing profits.

Increased Part-Sorting and Inspection Labor

Labor costs increase if employees have to comb through the parts post-process. Sorting by hand is costly and, even worse, unsuitable parts may still get through to your customer.

Expert Insight: Rich Seeley on long-term cost savings

A few years back, we interviewed Rich Seeley, former President and Owner of Midway Rotary Die Solutions on scrap removal, and his advice back then is still applicable today. “You may spend hundreds on a tool now that could save you thousands down the road. Why do by hand what tooling can do faster and cheaper?”

Check out more of Rich’s thoughts here:

Nine Capabilities to Boost Scrap Removal

The inefficiencies that scrap removal can cause can be quickly mitigated by adding the right in-line scrap removal system. We initially wrote this post a few years ago and featured capabilities. We’re updating it with the latest new capability from Midway Rotary Die.

All of these methods are effective, but which capability is most cost-effective depends on the particular application. Below we’ll detail some of the pros and cons of the solutions to get the decision-making process started.

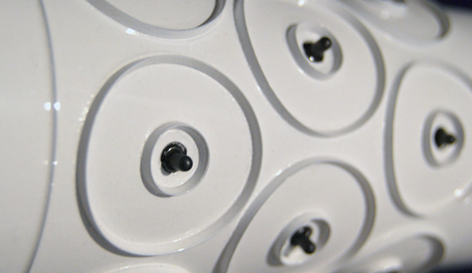

1. Ejection Pin (NEW)

This is the latest scrap removal technique, which features ejection pin technology that keeps slugs out of the rotary die cavity. The pin retracts into the die as the die rotates and the part is cut. Once the die rotates past the impact of the anvil, the pin emerges from the die, pierces the slug, and “ejects” or pushes the slug out into a disposal area.

Pros

- Allows ejection of small slugs not able to be ejected via air or vacuum

- No need for air source, additional equipment, or press modification

- Aids in removal of slugs on difficult or rigid material

Cons

- Higher cost

- Pins cannot be replaced in the field & must be sent in for replacement

2. Rubber / Neoprene Inserts / Foam

With this approach, material such as rubber, neoprene, foams and even liquid silicone products are applied to the cavities of the rotary die to prevent slug build-up.

These methods are inexpensive. However, their effectiveness is limited as they don’t provide much force against the slug, and may not ultimately separate the slug from the part.

Pros

- Inexpensive

- Simple to replace on-site

Cons

- Low force against the slug

- May not force slug completely from the die cut part

- Additional under-web vacuum is advised

3. Spring Plungers

Spring plungers offer an inexpensive method of slug/scrap removal that requires no press modification. The spring plunger is inserted into the rotary die to ensure slugs don’t get stuck in the cavity.

Spring plungers work well with rigid materials. Additional under-web vacuum helps in slug removal and collection.

Pros

- Positive mechanical method

- Relatively inexpensive

- Simple to replace on-site

Cons

- Limited ejection distance

- Additional under-web vacuum collection is advised

4. Standard Air Eject

With standard air eject, forced air is used to blow out the slugs. An air probe is inserted into the journal of the die to help direct the airflow, and forced air blows through the die cavities as the tool rotates. The use of an air probe reduces air consumption and noise.

Effective with small diameter dies, standard air eject is low-cost and easy to set up. Additional under-web vacuum helps in slug removal and collection.

Pros

- Relatively low cost

- Simple set-up

- Ease of use

Cons

- Limited air pressure through drilled holes

- Best when used with small slugs

- Additional under-web vacuum collection is advised

5. Pulse Air (Cavity Specific Forced Air)

With Pulse air, a single burst of air timed with the tool rotation ejects slugs at a specific point in the die’s rotation. This method reduces air consumption since the scrap only receives an air blast when needed. The intermittent air blast is the most effective air ejection system available.

It’s more expensive than standard air eject, as you need more machining with the die, but far more effective.

Pros

- High pressure air flow from each cavity

- More precise in directing air flow to specific cavities

- Flexibility in converting to vacuum transfer with manifold change

- Less noise compared to standard air eject

Cons

- Die cost may be higher depending on the quantity of radially drilled holes

- Additional under-web vacuum collection is advised

6. Vacuum Transfer w/ Pulse Air

The addition of vacuum transfer to a pulse air application allows the slugs to be held in the tool and transfer them to a preferred point of air ejection into a collection system.

It’s used when the part shape and the inner slug are cut metal-to-metal. It’s an ideal application if your space constraints will not allow for ejection near the point of the cut. This system requires an adequate vacuum source (typically a vacuum pump) and compressed air source for die.

This system is often used when “pick and place” of the part is required.

Pros

- Ideal for equipment that has limited space between stations

Cons

- Requires second vacuum to take slugs away from press

- Porous materials might not vacuum well

- Additional under-web vacuum collection is advised

7. Vacuum Thru (Inserts)

This method pulls the slug via a vacuum into the body of the die and then expels it out through the journal.

It’s not recommended if the part has adhesive. The inner slug must be cut M/M and the shape and size of the slug should allow for easy exit through the die.

Pros

- Eliminates need for multi-die setup

- Eliminates registration between two die stations

Cons

- Inserts require adequate spacing between insert blades and perimeter blades

- Can add significant costs to the die due to insert costs

- Required journal attached vacuum (shop vac) to remove scrap from tool

8. Stripping Pins

Stripping pins use sharp pins mounted in the anvil to pierce the slug and carry it to a comb system that removes the waste from the anvil. Use of stripping pins is the most effective scrap and slug removal system available.

Stripping pins are best used whenever scrap must be removed at high speeds. Pin systems remove outside matrix material scrap as well. Converting speeds over 1,000 fpm with 100% removal have been run. The “comb” system may be used in any future stripping pin application, as it is fully adjustable.

Pros

- Extremely effective, mechanical means for 100% removal and control of slugs

- Scrap and slug removal does not impede press speed

- Pins are removable/replaceable

Cons

- Cavities must be large enough to allow “sweep” of pins into cavities (Min Ø=0.250”)

- Requires matched stripping pin anvil roll and press must have a removable anvil

- Requires the addition of a “comb system” to remove slugs from the stripping anvil

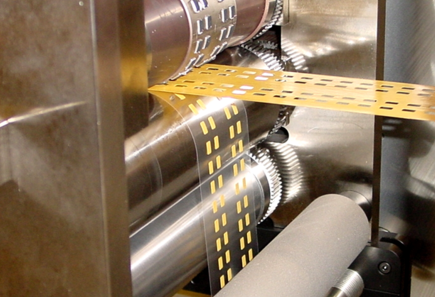

9. Sacrificial Liner

With the addition of a low-tack stripping tape, adhesive carries away slugs or other web waste. The low tack liner is introduced from under the anvil with the sticky side up towards the web. When the tool cuts, the scrap will adhere to the adhesive on the liner.

The sacrificial liner is then drawn straight down to a rewind with the scrap/slug on it. The web continues, away from the sacrificial liner, and the process continues.

This is an excellent option when scrap size is extremely small or there are no other slug removal options available.

Pros

- Eliminates mess – slugs stay with the sacrificial liner

- Used on multi-level cutting dies without metal-to-metal cutting

- Requires no additional tooling cost

- No equipment modification required

Cons

- Additional cost of the sacrificial liner

- Additional web rewinds may be required

Hundreds vs. Thousands: Pay it Now or Pay a Lot More Later

You have scrap removal options. The key is matching the right option with the right application. It all depends on the variables associated with the job.

A lot of factors need to be considered, but it’s well worth the upfront consideration. As Rich Seeley notes, “The whole purpose of rotary converting is high speed, low cost production. Raw material in, finished parts out with minimal labor input.”

To learn more how to improve production while minimizing labor input with scrap and slug removal, either contact us online or call 1-763-755-7744.

OVERCOME YOUR BIGGEST CONVERTING AND PACKAGING CHALLENGES

Published on Mar 30 2023

Categories: Delta ModTech Blog, Reducing Scrap

Tags: Die-Cutting Machines, Die-Cutting Process, Slug Removal

Next Post

Foam Expo North America 2023

Previous Post

RFID Journal LIVE 2023