Serving People…

by Solving Problems

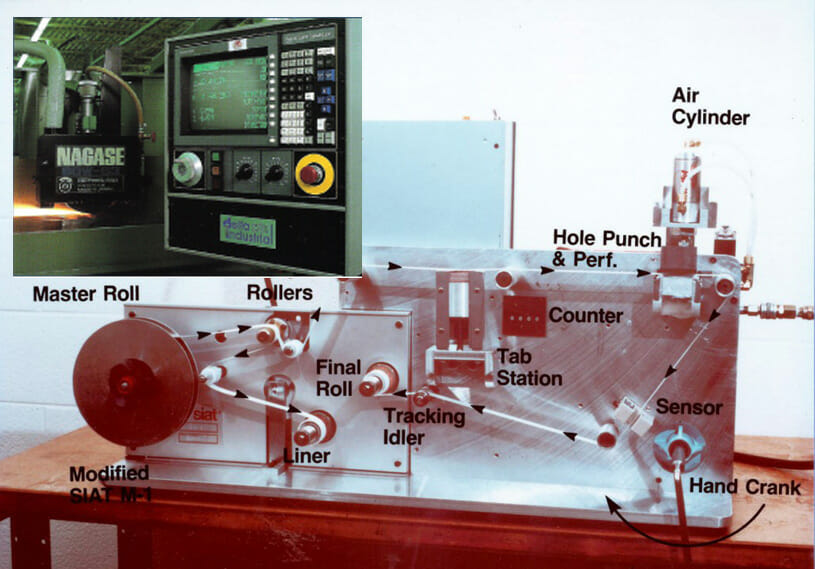

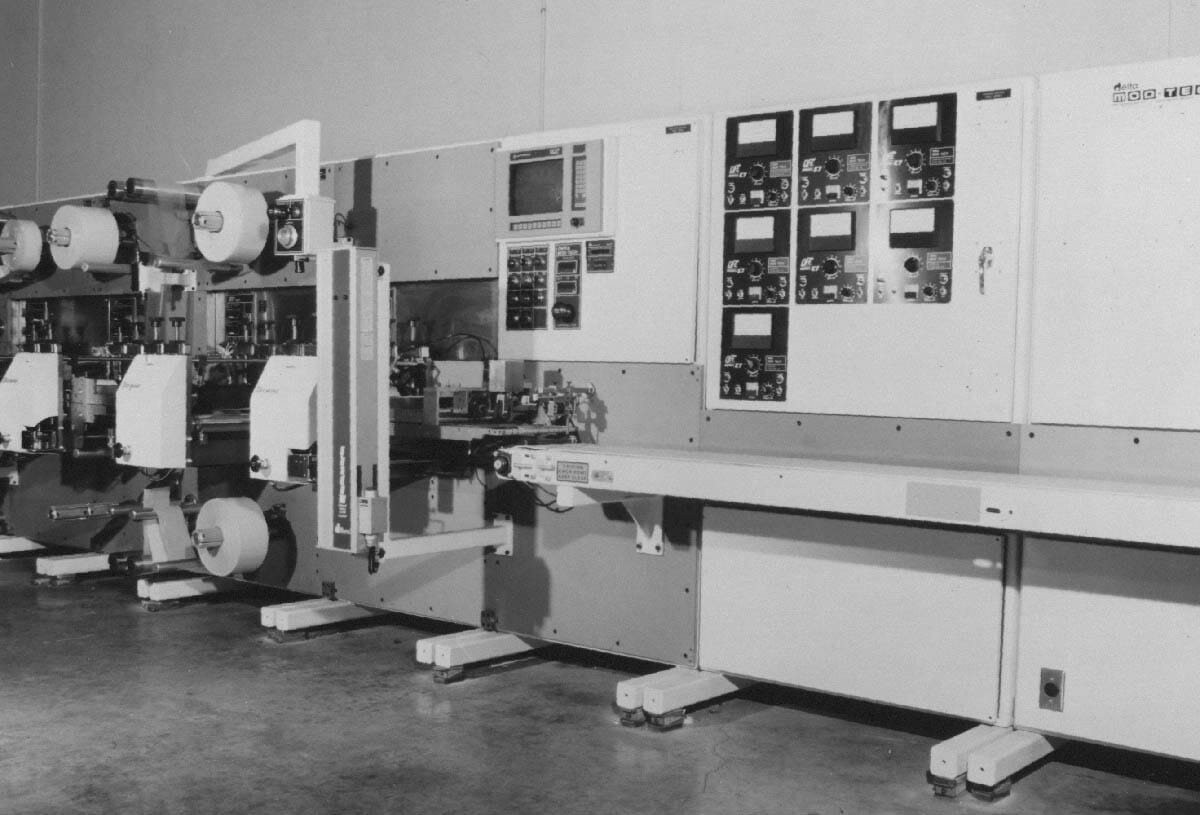

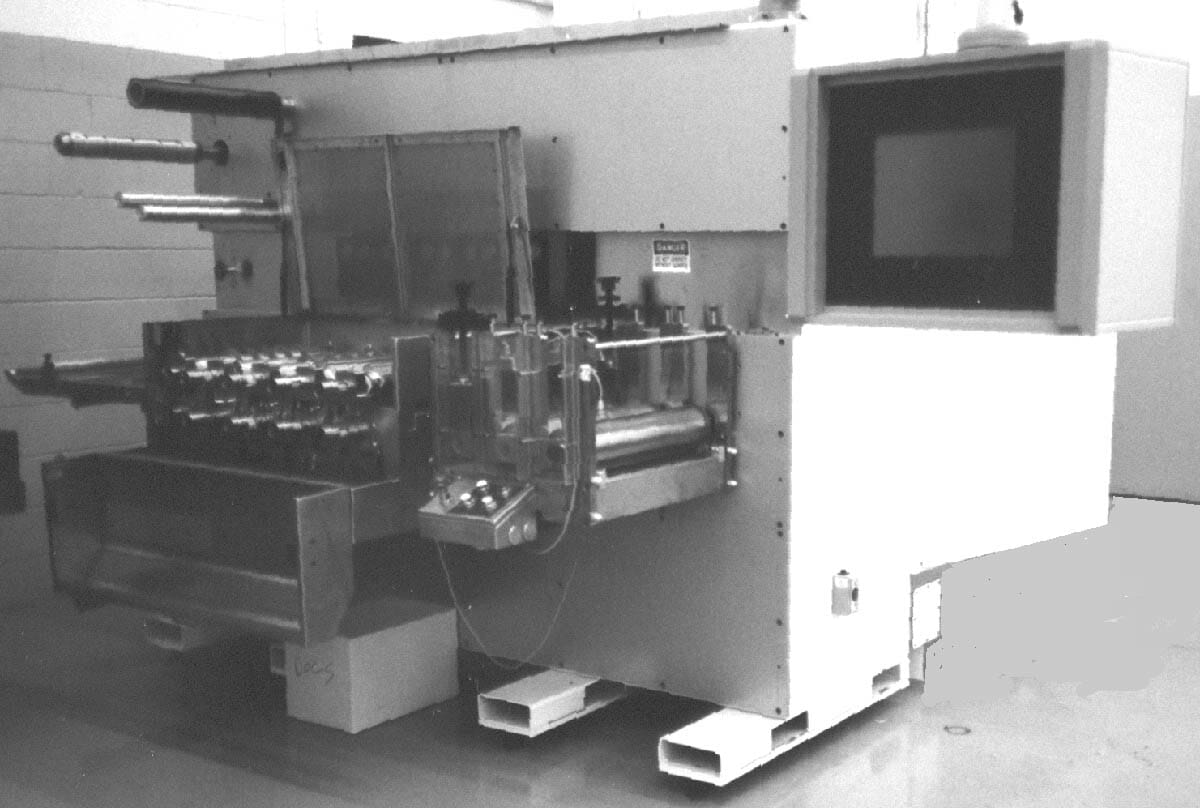

From our founding in 1978 as a service provider for servo systems and motion control in the machine tool industry, to today’s technology of full production Delta ModTech converting and packaging lines, Delta ModTech has successfully pursued excellence in the design, implementation, and service of motion-controlled converting and packaging systems.

In 2016 Delta ModTech acquired Frontier LLC out of Towanda PA for their expertise in coating equipment. They fully merged with Delta in 2023 and allow us to offer customers the total solution for converting and coating equipment.

Contact us today and we can set up a confidential meeting to discuss your project.

Our Mission

Thriving on challenge.

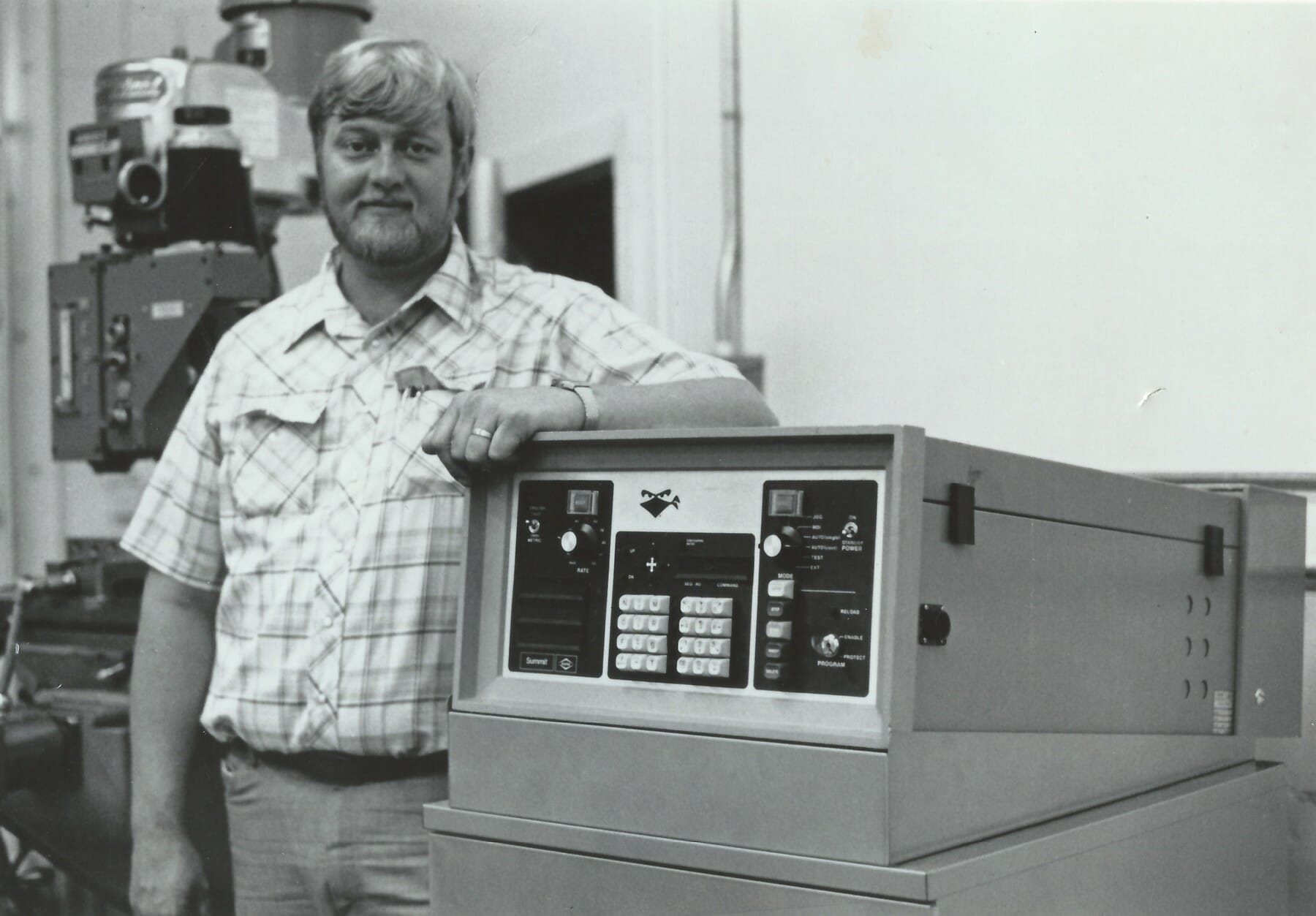

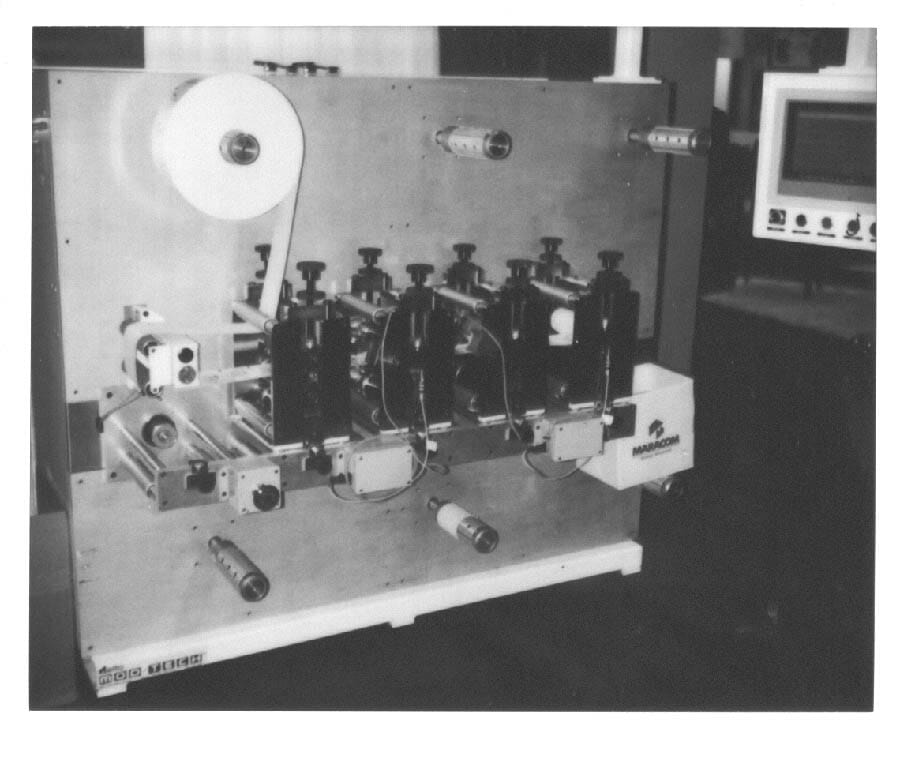

We’ve been taking on the tough jobs from day one. We started in web converting with the challenge to build a better web converter than the line shafted machines of the time. Our founder, Dave Schiebout, knew that computer control and servo drives would provide more flexibility, speed and tighter tolerances than any line shafted machine… but it had never been done. “It would never work.”

Instead of listening to naysayers, we prevailed with the first Delta converter. Through software development we found the heart of each converter, the control system. Coupled with solid mechanics, a new bar had been set. Digital control is the future and it’s a platform we’ve been building off ever since.

Reduce Risk.

When you face new challenges each day, you can’t waste time starting from scratch each time. We knew we needed to have the basics down to take on new challenges so we used our engineering expertise to develop a platform of converting modules that are flexible, proven and robust.

Each new project follows the same process: pick out the high risk and difficult to manufacture areas, review requirements, add our proven modules and present a solution with confidence. Quick turnaround, punctual communication and shorter lead times gets your product to market fast.

If your product or materials are still in the development phase, our in-house R&D facility gives us the ability to prove we can do it. Through our Proof of Principle Process, we can take your materials in-house and develop a manufacturing solution that will meet production requirements. This can be a detrimental part of the process and can help with our customers to develop material.

Service, service, service.

Service has always been our top priority. Whether it be changes in process, hardware, software or troubleshooting, we have built a culture around serving our customers. We know that every minute of downtime cost money, so we do whatever it takes to get them up and running. When you call us, you will talk to a live, experienced service representative who has intimate knowledge of your machine. Our software allows us to connect to your machine through the internet to perform software upgrades and troubleshooting without the cost associated with expensive service visits.

Our greatest asset? Our team.

Delta ModTech is well versed in the latest technology; our engineers are driven to maintain and expand their engineering knowledge through hands-on experience as well as continuing education and product training.

To ensure that we meet our customer’s challenging needs, we strive to employ the most creative and innovative individuals. Delta ModTech’s hiring and management practices empower individuals, who are open to change and growth; we are always interested in ways to improve.

Delta ModTech’s History

Quality Management

Repeatable processes ensure quality results.

Using the guidelines of the ISO 9001:2015 standard, our Quality System has given us the ability to increase the quality of our products and services while maintaining our unique organizational structure. Through employee mentorship, on/offsite training, work procedures, process audits, and customer feedback, Delta ModTech has been continually adapting and improving its quality system to meet the needs of its customers and the industry. Our Quality System Certification has been active since 1999 and is assessed and certified by SGS North America, Inc.

Press Releases: get the scoop on Delta ModTech

Delta ModTech Expands Service in Europe

Delta ModTech Expands Service in Europe

New European Service & Support Team As Delta ModTech continues to expand their global reach, the desire to maintain world class service has only grown.…

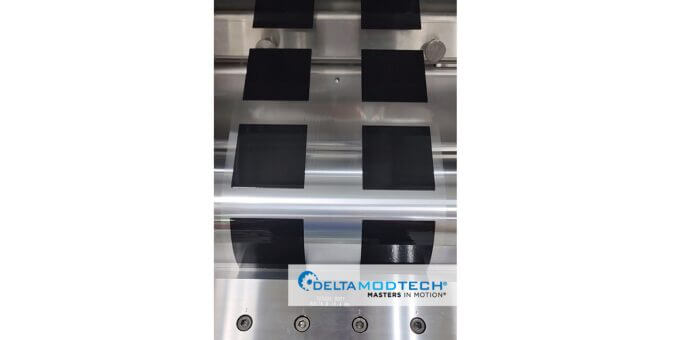

Advances in Slot-Die Patch-Coating Could Revolutionize Li-Ion Battery Manufacturing

Advances in Slot-Die Patch-Coating Could Revolutionize Li-Ion Battery Manufacturing

See how the latest developments in slot-die’s patch-coating capability could revolutionize the lithium ion battery industry.

PLI Fabrication Adds New Converting Capabilities, Transforming Company Capacity and Performance

PLI Fabrication Adds New Converting Capabilities, Transforming Company Capacity and Performance

Learn how PLI Fabrication transformed its capacity and overall performance with the help of Delta ModTech.