Transdermal Manufacturing

From Coating to Converting,

Excellence Every Step of the Way.

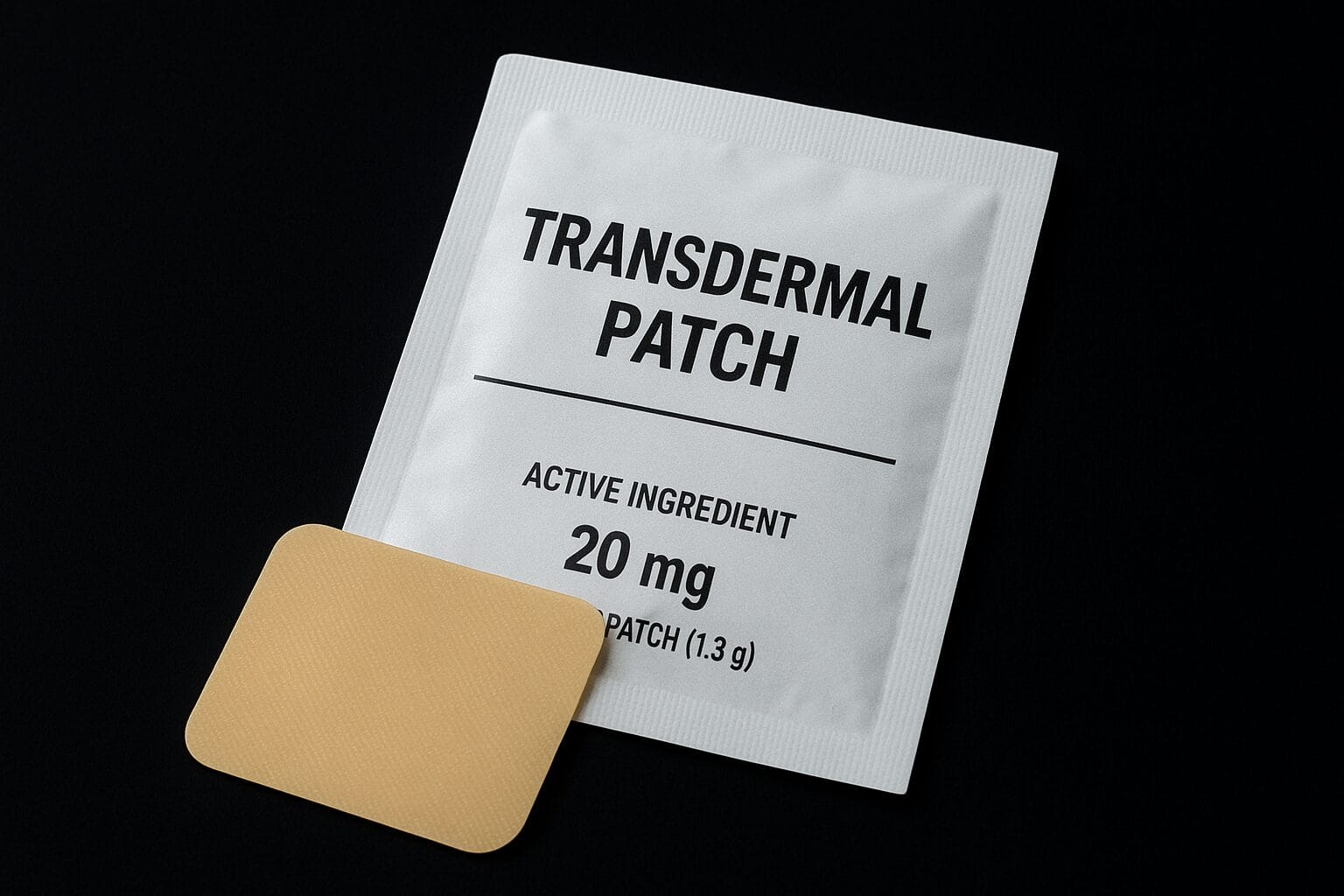

End-to-End Expertise in Transdermal Manufacturing

Delta ModTech delivers unmatched expertise in both coating and converting for transdermal patch production. Giving you a complete partner providing purpose-built systems, that ensure you gain the efficiency, accuracy, and compliance needed to be successful in today’s market. From precise drug-layer coating to complex die cutting, inspection, and packaging, Delta ModTech provides a seamless path from raw materials to finished patches.

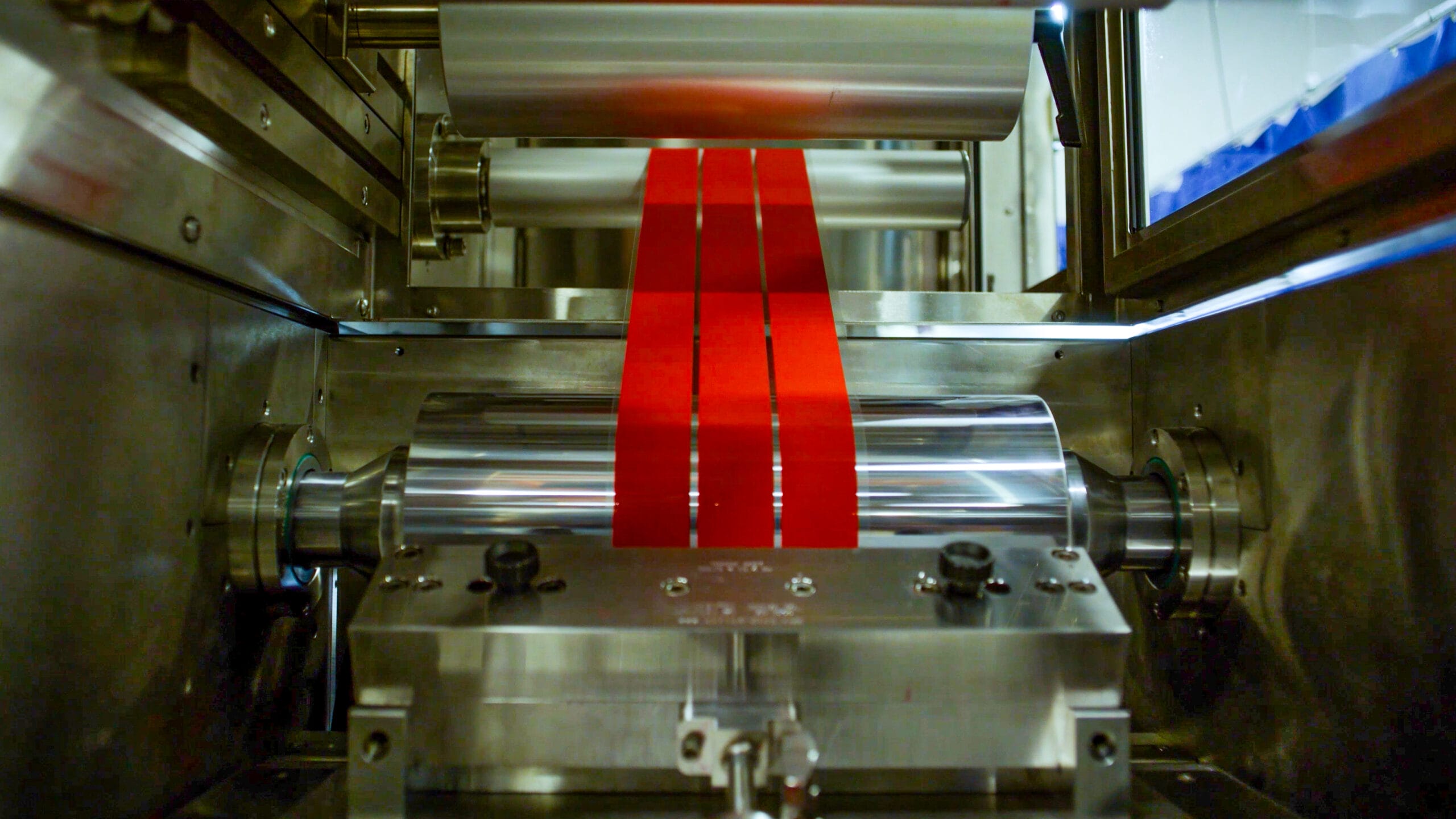

Transdermal Demo

In this video we demonstrate our precise slot die coating technology that minimizes waste and ensures consistent coating thickness across the substrate, providing a cost effective and compliant manufacturing solution.

Overcoming Common Transdermal Manufacturing Challenges

Producing transdermal drug delivery systems requires stringent process control. Manufacturers must manage drug deposition accuracy, complex material handling, while minimizing waste and maintaining compliance. Without consistency between coating and converting systems, bottlenecks and inconsistencies often emerge, slowing production and adding risk. These are challenges were Delta ModTech thrives…

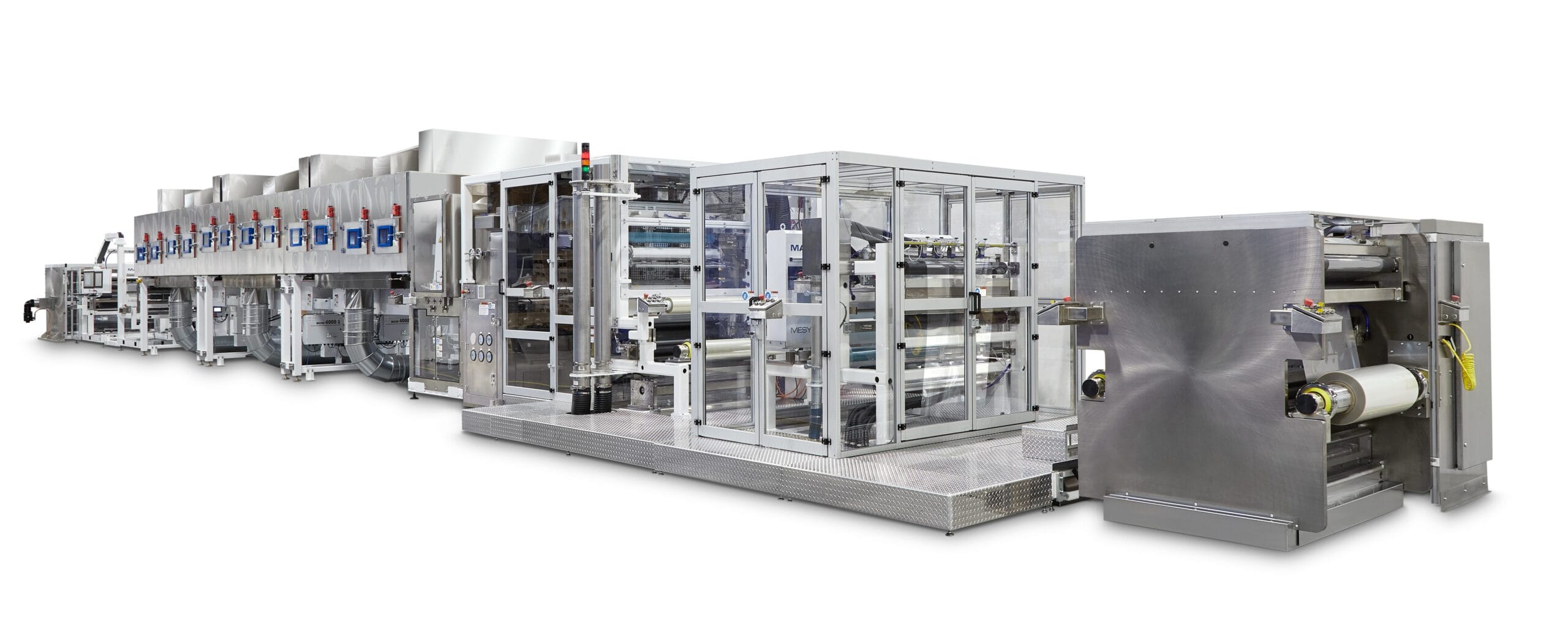

A Streamlined Workflow from Coating to Converting

Our coating systems deliver precise drug-layer application with consistency and control. Once coated webs are prepared, Delta ModTech’s converting systems take over, integrating lamination, precision die cutting, inline inspection, lot/date coding, and final packaging.

Advanced Capabilities for Precision and Flexibility

Our modular systems feature servomotor precision, advanced recipe management, and optimized die-cutting strategies for reduced scrap. Our customers report material savings of 10–50% after implementing a Delta ModTech solution.

With a scalable and modular design, our systems evolve with you, supporting R&D, clinical trials, and full-scale production.

Machines that raise the bar in Transdermal Manufacturing

Delta ModTech’s systems are highly customizable for multiple product sizes and configurations.

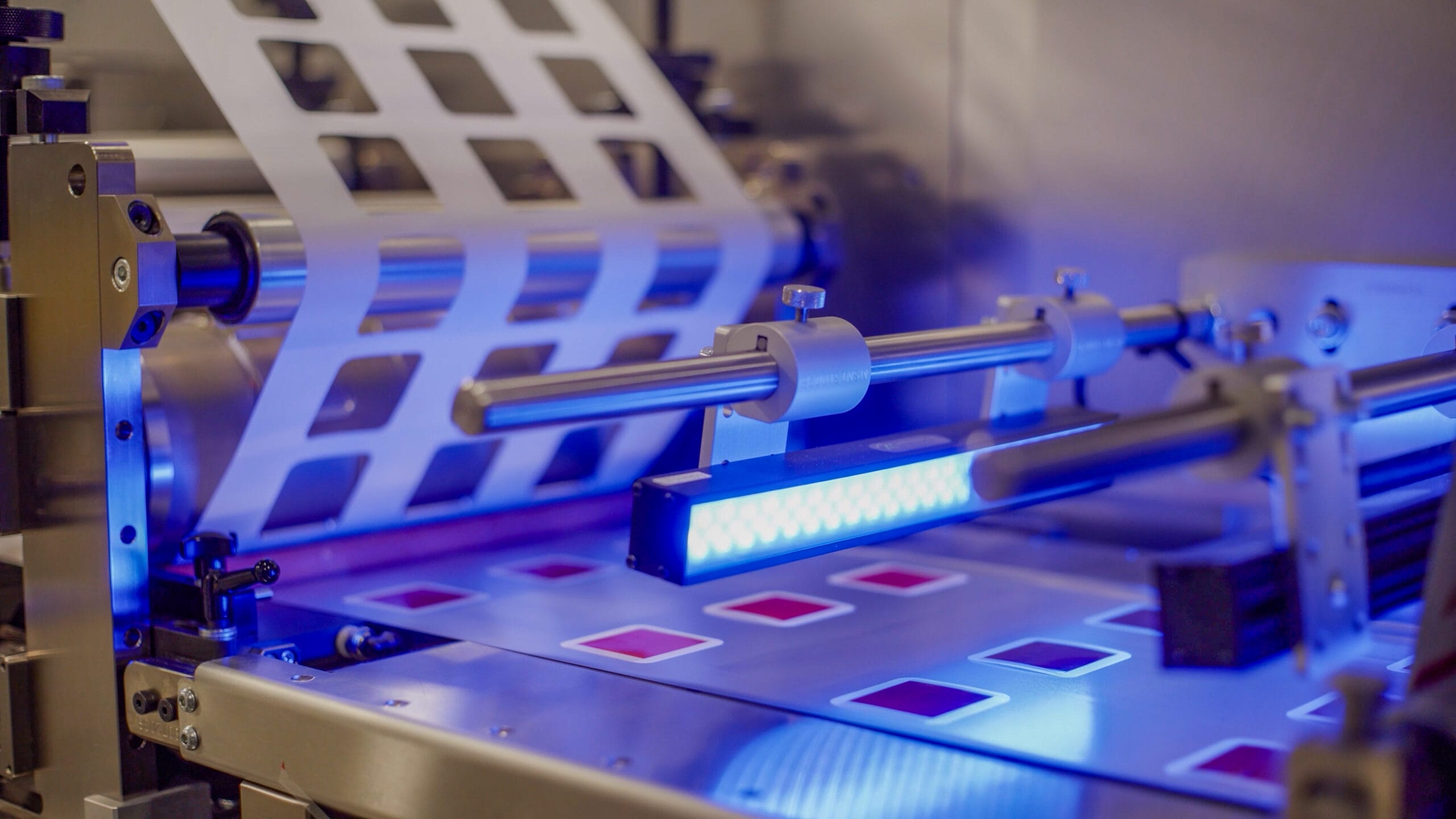

die cutting and placement technologies

Our advanced die-cutting and placement technologies allow smaller, more precise cuts with less scrap, maximizing drug utilization. Additional savings can be achieved by pairing our die-cutting modules with the MOD-TRACK® Vision System for real-time, closed-loop cutting corrections.

Reject, shingling and stacking

Our conveying modules support a variety of part-handling functions to ensure quality product verification. Reject conveyors remove non-conforming parts with multiple lane options. Shingling and stacking conveyors enable precise part counts, while spreading and transfer conveyors are designed for specific process requirements.

Precision Coating & drying

Our slot die coating technology set the industry standard for precise coating thickness. Our expertise in modular design is prominent in our coating and drying equipment, this design gives the capability to add features like weight gauge and scanning systems, lamination, and changeable coating heads.

end-of-line Integration

Through our Masters in Motion® expertise, we seamlessly integrate OEM packaging and robotic systems into complete automated manufacturing lines—all controlled from a single touchscreen HMI.

Lot / date code printing

Our systems integrate lot and date code printers that can be programmed directly from the machine’s touchscreen interface and tie into factory automation systems.

Validation support for IQ/OQ/PQ

Accelerate time to market with our experienced validation team. Leveraging proven machine modules and a variety of converting processes, our validation and commissioning services, can be tailored to your project’s requirements.

Vision inspection

Our MOD-TRACK® Vision System verifies product quality and can update registration positions automatically, helping maintain the highest CPK values for your process.

Heat-seal pouching

Our patented heat-seal technology delivers repeatable sealing time, temperature, and pressure settings—maintaining high-speed, continuous motion in tandem with the converting process.

CFR 21 Part 11 Compliance Tools

We deliver high-quality systems with built-in capabilities to comply with 21 CFR Part 11 and streamline machine validation.

From curious questions to preparing a quote, we’re ready to help.

Whether we’re answering some introductory questions or if you’re in need of a quote, just fill in the form or call us at 1-800-279-3358 and we can get you the answers you need.