Unmatched Flexibility for Label Finishing and Converting.

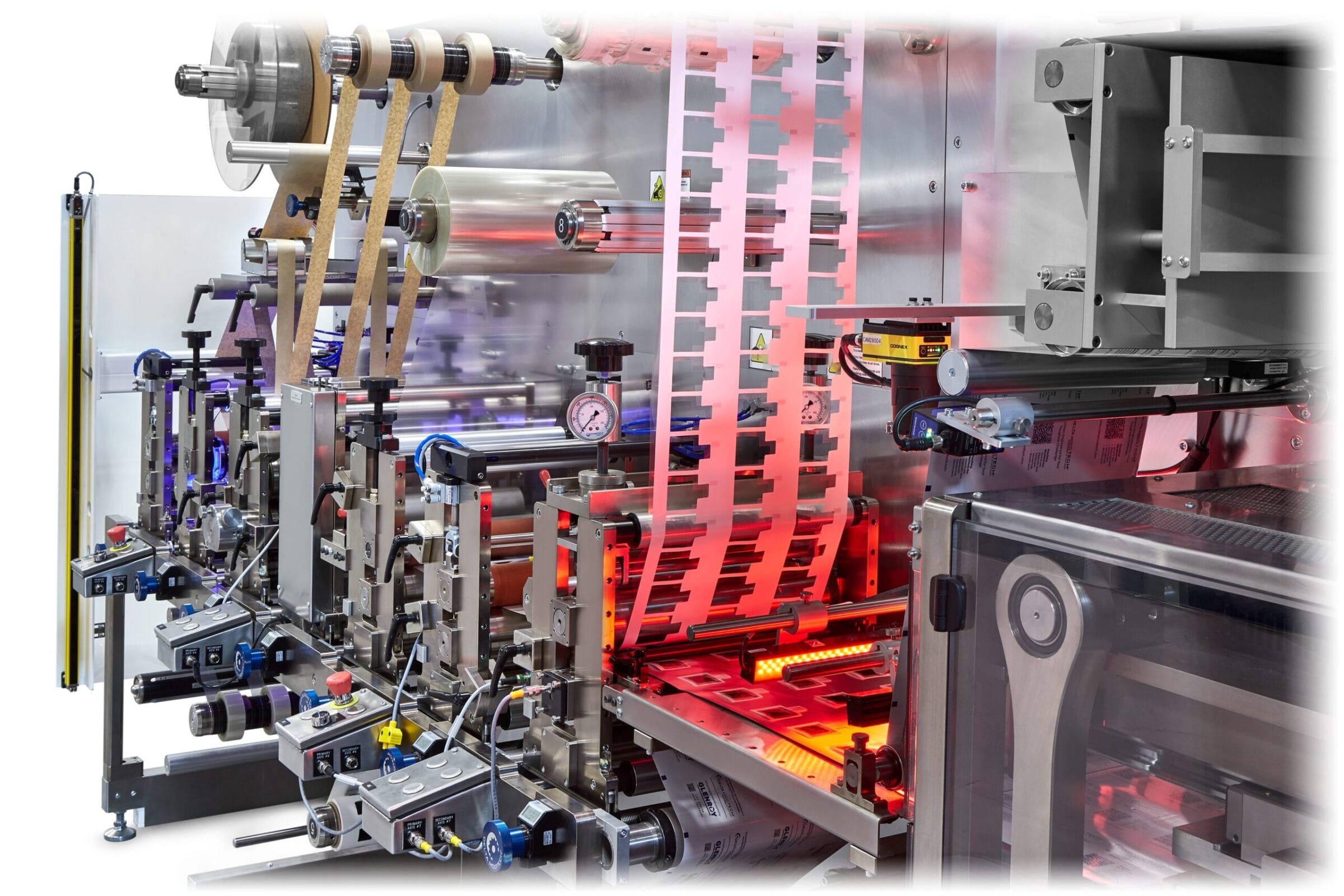

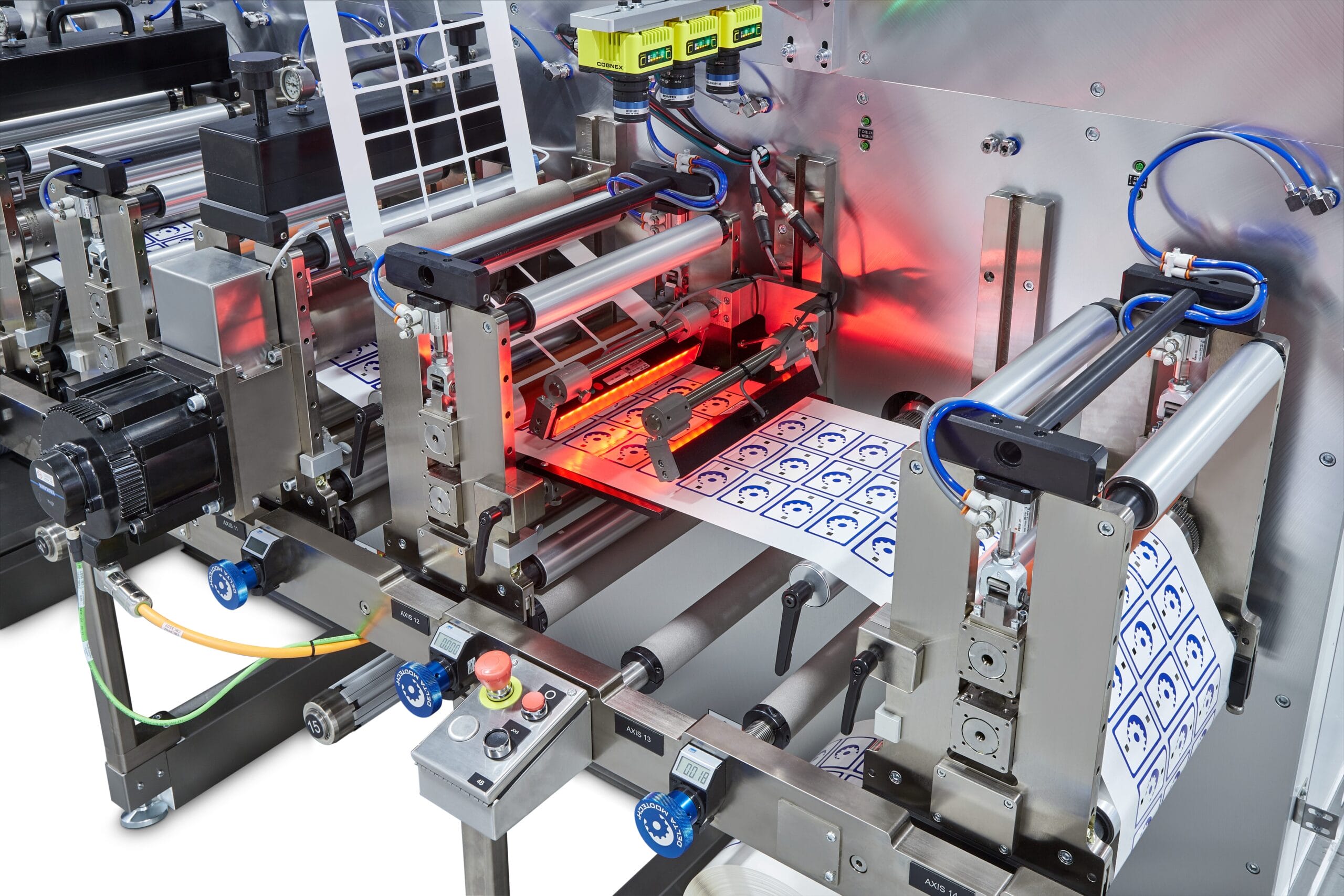

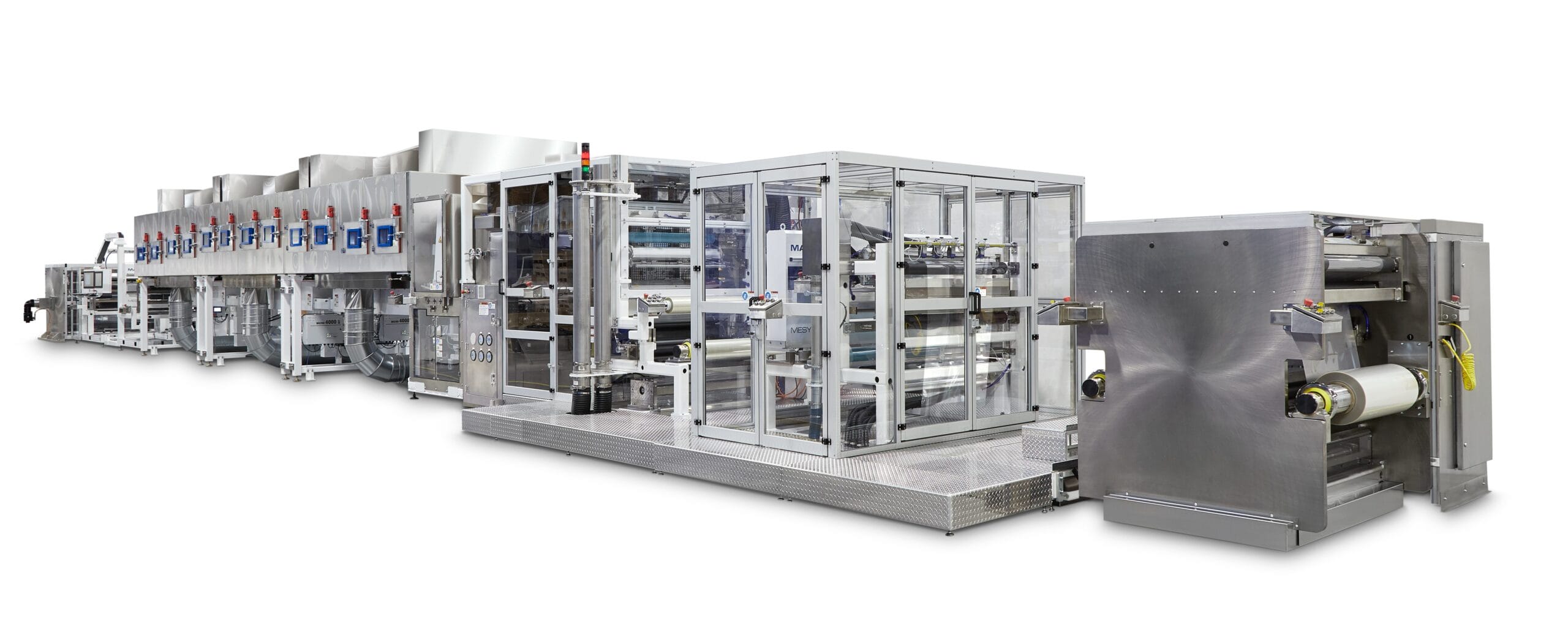

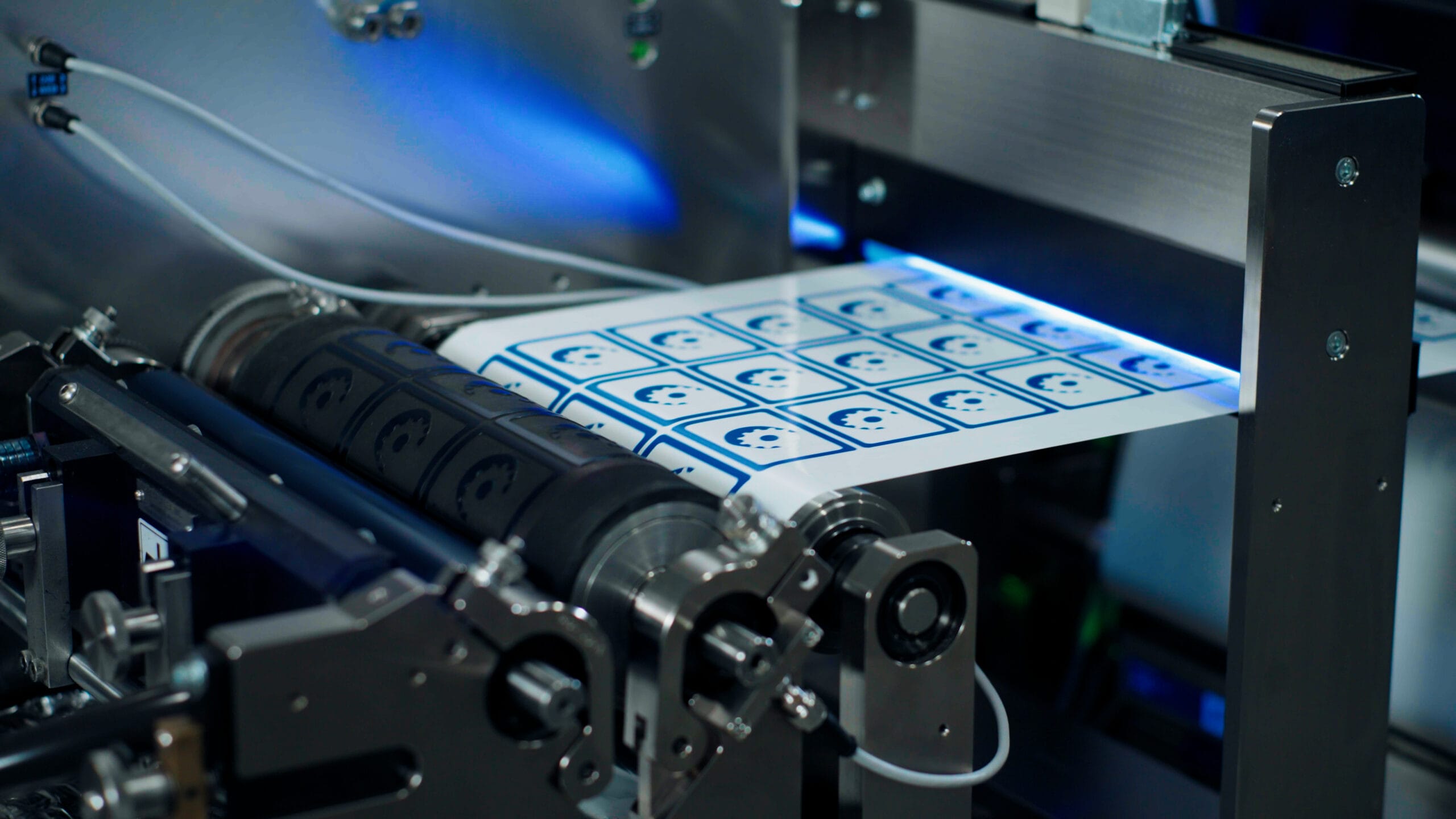

Whether you’re finishing digitally printed labels, die-cutting complex shapes, quick change laser cutting— Delta ModTech systems are built to meet your demands. With modular components and precision registration control, you can configure a system tailored to your exact needs.

Machines Designed to Deliver

Our converting equipment can accommodate just about any combination of printing and finishing technologies your jobs require. With a legacy of innovation as the first to offer a modular converting platform, Delta delivers proven flexibility—empowering you to expand capabilities over time without disruptive or costly overhauls.

Capabilities

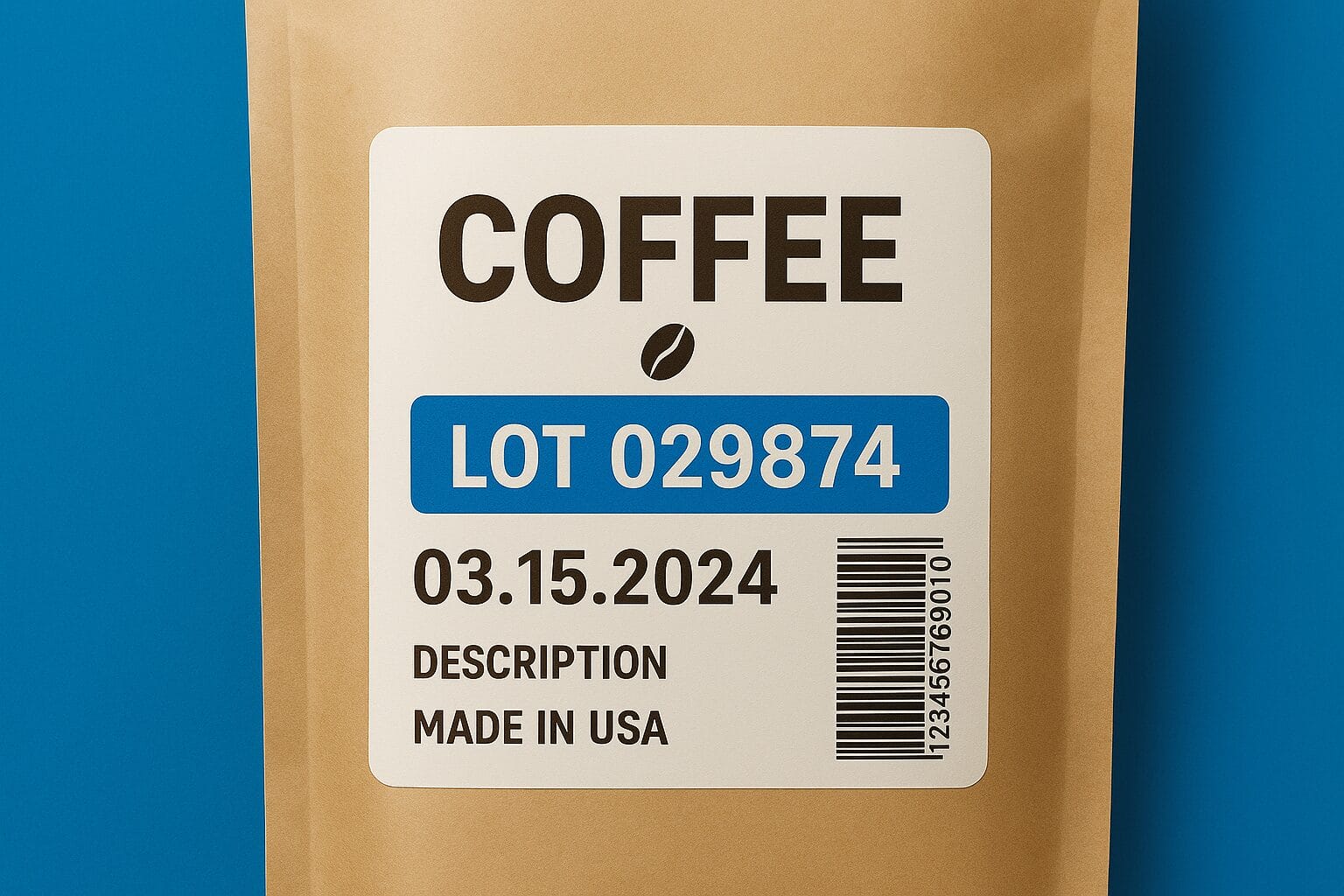

Delta ModTech’s converting systems offer advanced capabilities including rotary, semi-rotary and laser die cutting, laminating with liner replacement, discrete tag insertion and precise slitting and rewinding. In-line inspection and vision systems ensure quality control, while sheeting and stacking streamline product handling. Our equipment features re-registration for accurate alignment with pre-printed materials