From pharmaceutical serialization to smart labels in retail, RFID is being adopted for its security, high-speed performance, and ability to identify without line-of-sight scanning. But…

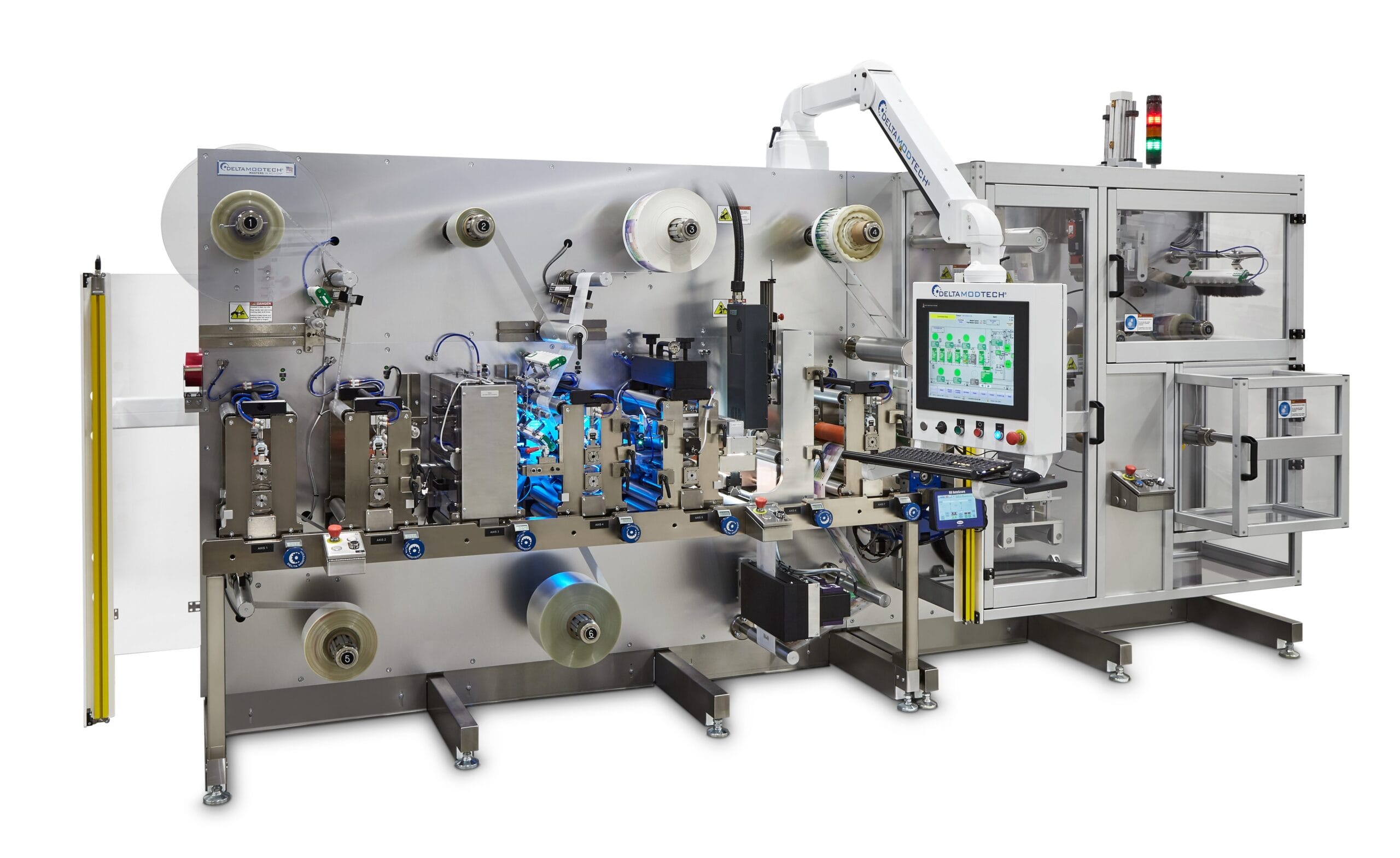

RFID Converting Machines

Engineered For Speed, Built For Precision.

Insert, Read, Write, & Verify — All In One Seamless Pass.

Solve the Challenges of RFID Tag Insertion!

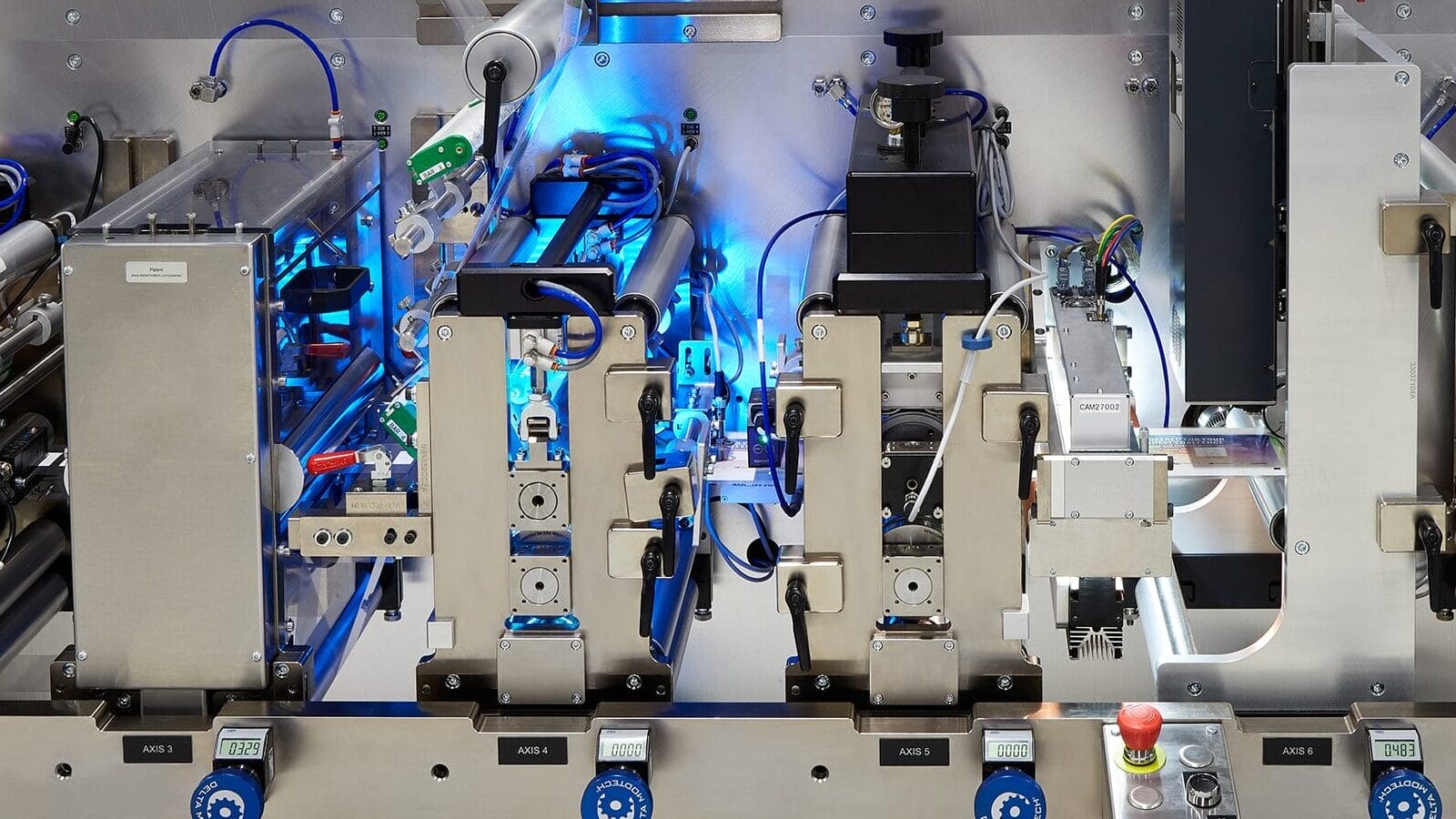

Our patented Island Transfer and Island Placement modules allow for the fastest, most precise RFID tag insertion.

Inserting pre-made RFID tags shouldn’t slow you down. For many converters, it’s a process that demands flawless precision and often leads to lost time and material waste.

At Delta ModTech, we make RFID tag insertion faster, cleaner, and more precise. Our patented Island Transfer and Island Placement insertion modules are designed to deliver high-speed, high-precision RFID tag insertion while also minimizing waste.

Whether you’re producing smart labels, packaging, or security products, our RFID insertion modules help you stay competitive by improving accuracy, reducing scrap, and maximizing uptime.

RFID Inlay Demonstration

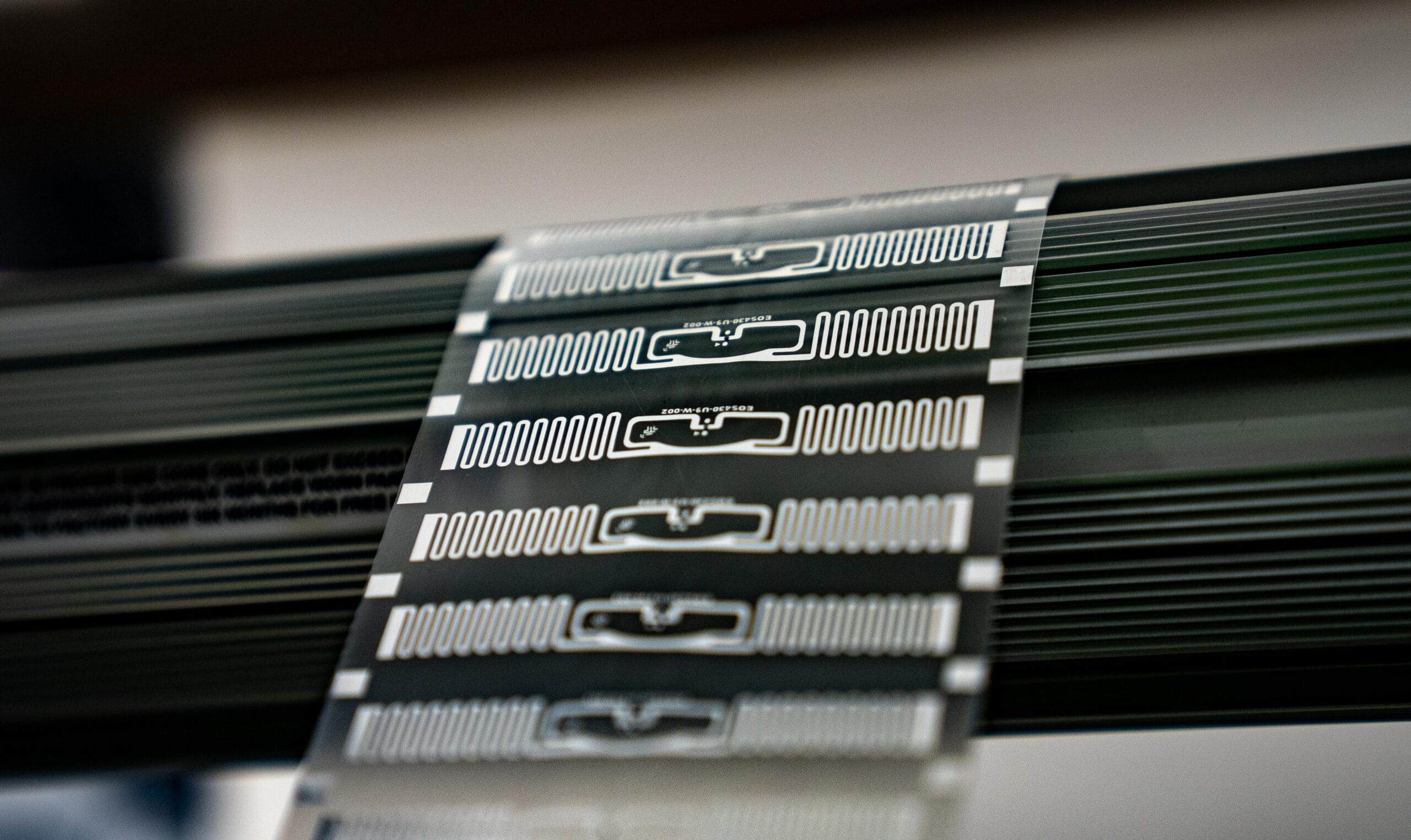

In this video, we’re placing .71″ [18mm] RFID tags on 6.25″ [159mm] labels at 480+ tags per minute while encoding each RFID tag with it’s own unique 96-bit Electronic Product Code (EPC). That’s a web speed of 250 feet per minute [76 meters per minute] using Delta ModTech’s patented Island Transfer Process and Delta’s modular Crusader Converter. Faster speeds are available – up to 2,500+ parts per minute!

Offering a Better Way to Create RFID Tags

RFID tag technology can be confusing. Which tag is right for your needs? And what’s the best way to produce them?

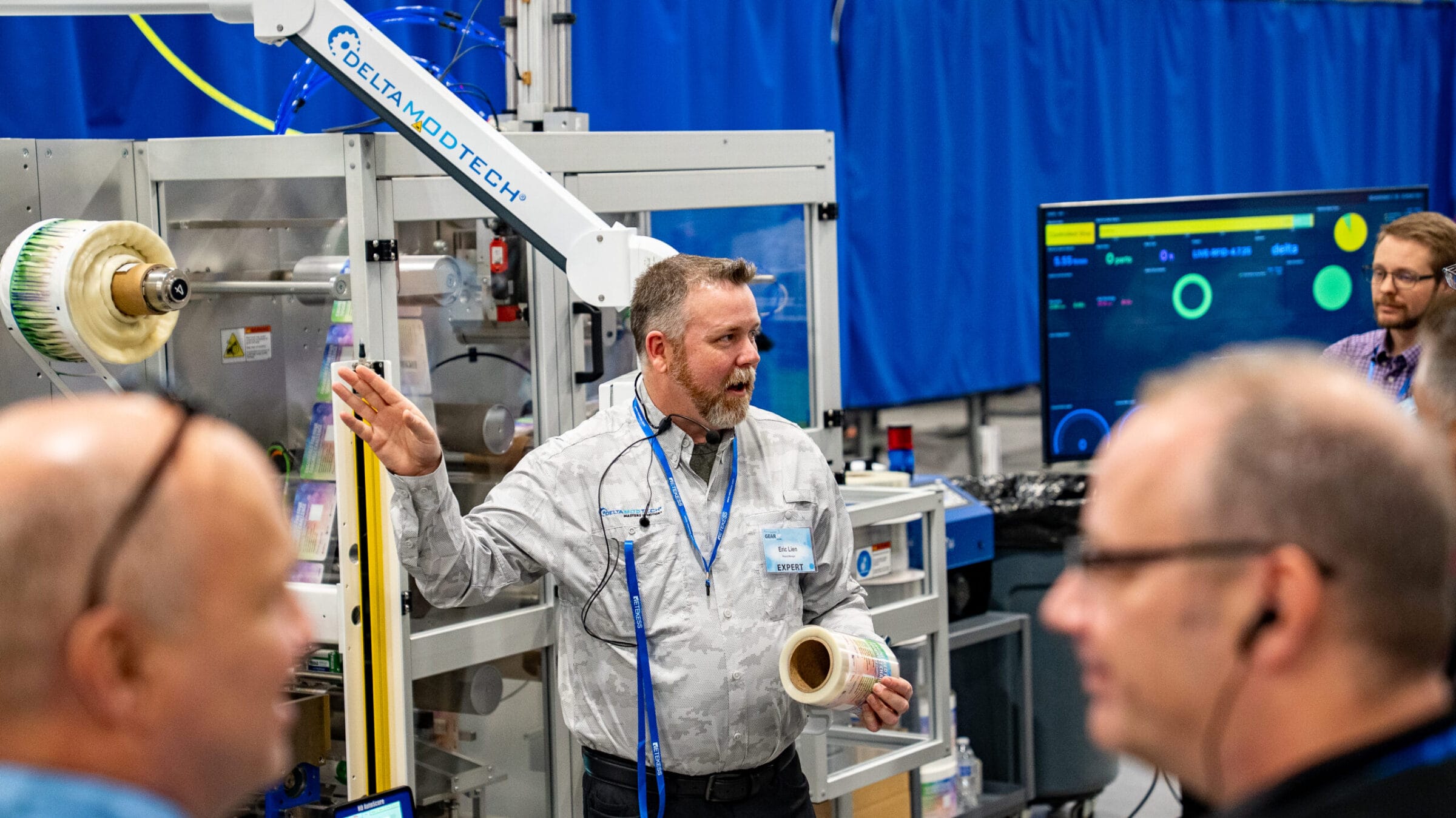

With 20+ years of RFID experience and our patented Island Transfer and Island Placement modules, Delta ModTech can guide you through the complexities of RFID technology.

Our machines can assemble, program, and test your RFID tags. Need your tags for later use? Our machines can also rewind assembled inlays. Alternatively, our machines can insert wet and dry inlays into finished labels.

Providing Proven Insertion Methods to Meet Your Requirements

To meet your RFID needs, Delta ModTech offers proven process modules compatible with our Crusader® Converter or our more advanced DMT Converter: the Island Transfer Module, Island Placement Module, and the Automated Rewind Turret.

Benefits include:

- High-speed insertion

- Precision placement

- Minimal downtime

- Minimal waste

- Proven methods to mitigate risk

- Delta press compatible

RFID Assembly and Insertion

When it comes to manufacturing RFID tags, there’s little to no room for error when joining the antenna and circuit.

Thanks to Delta’s advanced servo controls and robust registration software, our machines allow you to manufacture RFID tags with high precision and limited operator interaction.

Programming RFID Tags

Our team of experts can give you the ability to encode (i.e., program) RFID tags inline. Because of our comprehensive expertise with RFID integration, we can develop a total solution for writing, reading, and verifying tags in one pass.

Experience with all RFID tagging systems

There are three main types of RFID tagging and reader systems. Delta ModTech has valuable experience working with all of them:

- Passive Reader Active Tag (PRAT)

- Active Reader Passive Tag (ARPT)

- Active Reader Active Tag (ARAT)

Delta ModTech’s History With RFID

At Delta ModTech, we have built a reputation for delivering precision label processing solutions that meet the tightest tolerances — from intricate die-cutting to accurate discrete part placement.

For nearly 20+ years, we have been at the forefront of RFID production and led the way for RFID manufacturers. Our expertise has helped from helping customers produce RFID tags in mass quantities to help them automate RFID tag insertion.

Today, there are hundreds of machines using our RFID placement technology, and more than 50 machines are being used specifically for RFID manufacturing.

RFID FAQs

What is an RFID?

RFID, or radio frequency identification, is a form of wireless communication that uses a tiny tag (sometimes called a transponder). The tag is made up of an antenna, a substrate, and a circuit and can be attached to items to track their locations and store information.

RFID technology has become an integral part of manufacturing and has an array of potential applications, from opening locked doors with a key card to tracking a pet’s location to indicating inventory levels for a retailer.

How do RFID tags work?

RFID tags (or transponders) contain information that is transmitted with radio waves via an RFID reader. Depending on the RFID system, tags can be passive, active, or semi-passive. Because multiple RFID tags can be read simultaneously, they are considered a more efficient option than barcodes, which require being individually in the line of sight of a barcode reader.

Your Next Delta ModTech Machine Could Be Ready Right Now

In-Stock Machines. Proven Quality. Quick Turnaround.

Discover our current selection of precision converting and packaging machines available for immediate or short-lead delivery. These in-stock Delta ModTech systems offer the same proven performance, reliability, and quality as our custom builds, just with a faster turnaround. Browse available models, request pricing, and get your production running sooner.

Let’s Talk RFID Manufacturing Solutions!

Fill out the form below to meet with us at an upcoming tradeshow or visit one of our showrooms in Ramsey, Minnesota, USA, or Hisings Backa, Sweden. Contact us to set up an appointment today!

Metalcraft Cuts Converting Times in Half AND Creates Award-Winning RFID-Enabled Solutions in the Process

June 19, 2024

See how Metalcraft has cut its RFID product converting time in half AND how Delta ModTech has helped the company create innovative RFID solutions.

Innovative print manufacturer Meyers excels in RFID labeling with the help of Delta ModTech.

Bring Us Your Toughest Challenge

Whether you’re a manufacturer assembling RFIDs or a manufacturer trying to meet Walmart’s new RFID mandate, you need the right equipment to get the job done. At Delta ModTech, we have been on the cutting edge of the RFID industry, from helping customers produce RFID tags in mass quantities, to helping companies automate the placement of these RFID tags. With our proven expertise and patented technology, you can count on us to deliver the speed, accuracy, and reliability you need to stay ahead of the curve — and ahead of your competition. Let us help you streamline your RFID production, reduce waste, and meet even the toughest industry requirements with total confidence.