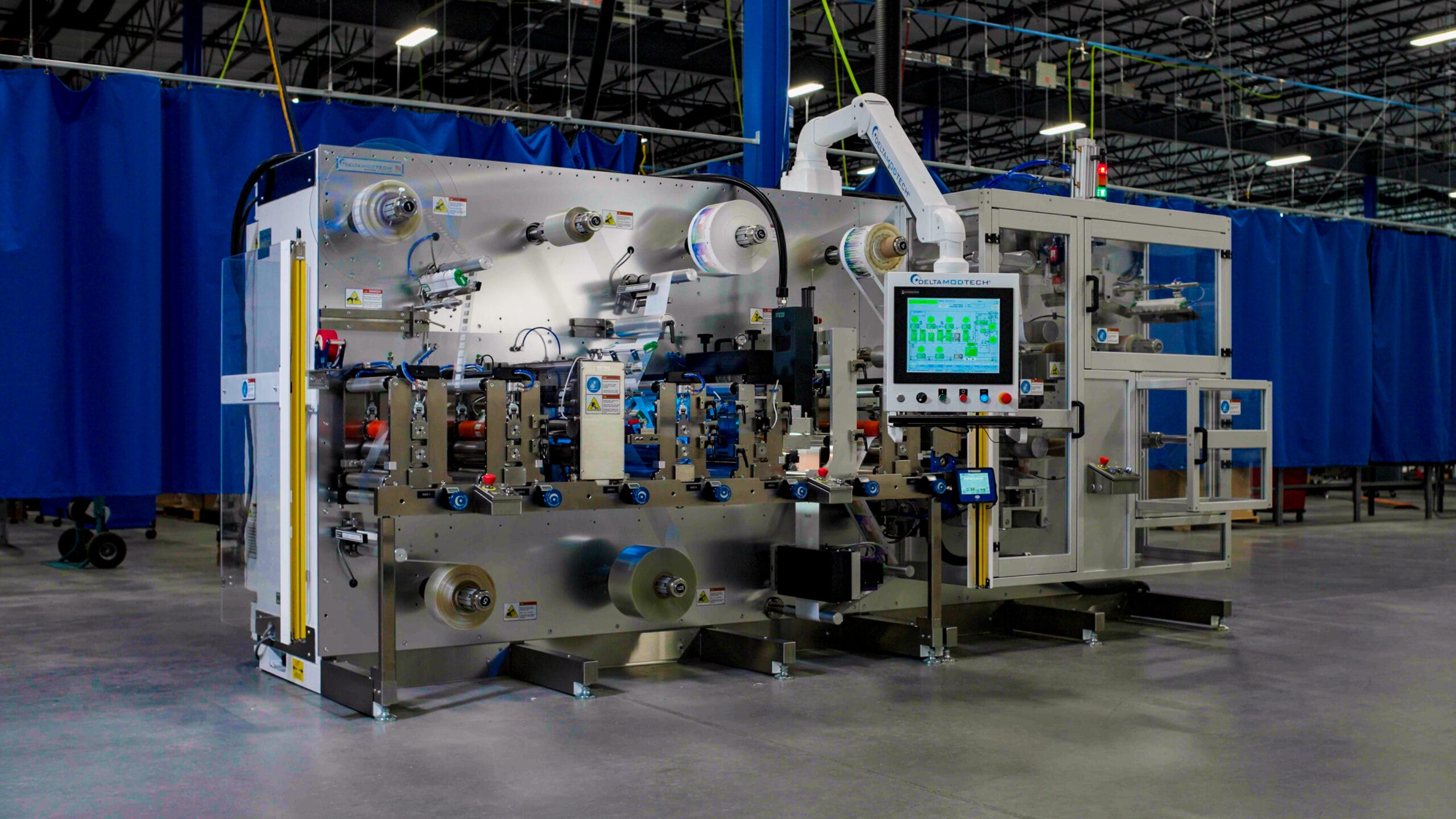

Engineered for Your Toughest Challenge

From tight tolerance die cutting to unique pouching requirements, our machines are engineered for your toughest challenge.

Learn More

Learn MoreConverting

Building complete web converting and packaging machines out of proven, flexible modules.

Learn More

Learn MoreCoating

We continue to innovate with new coating and drying technologies for the most complex products.

Learn More

Learn MoreSupport

Servicing our customer’s needs has always been Delta’s highest priority.

Learn More

Learn MoreMachines Ready to Ship

See a list of current machines Delta ModTech has in stock available for short lead times.

Learn More

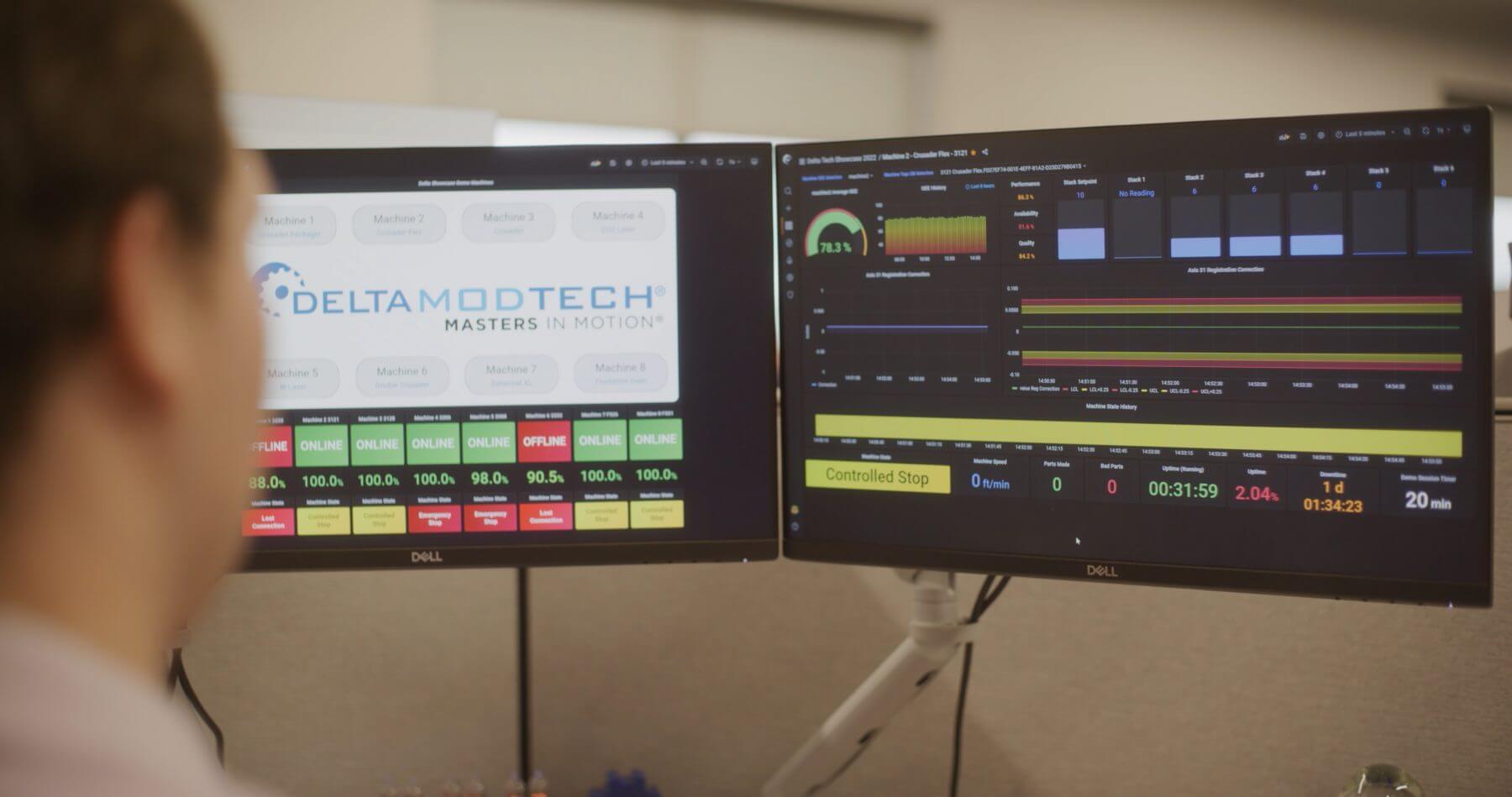

Learn MoreModTech CONNECT™

ModTech CONNECT™ empowers manufacturers to harness real-time and historical machine metrics.

Learn More

Learn MoreMarkets Served

Whether you’re creating advanced medical devices or packaging consumer products, our modular systems empower you to manufacture with speed, accuracy, and confidence.

Learn More

Learn MoreCase Studies

Delta ModTech has consistently delivered excellence in motion-controlled converting and packaging systems

Learn More

Learn MoreAbout Us

Delta ModTech has provided quality engineering and service for 40 years.

Learn More

Learn MoreBlog

Offering expert advice on enhancing converting and web flow manufacturing processes, with insights from Delta ModTech and industry experts.

Let us prove we’re up for the challenge.

Try us. Many have, bringing us their most complicated challenges. Our team always finds an innovative converting machine solution to help clients with:

- Difficult web manufacturing and finishing problems

- Ambitious production goals

- Exacting requirements and challenging regulations

Click the Request a Quote button to find out how we will deliver!