5 Reasons You Need a Closed-Loop Vision System (and a Few Why You Don’t)

Closed-loop vision systems are an exceptional way to increase your production efficiency, as we’ve detailed in our post “Should You Automate Corrections in Real Time?”

Vision system are hot. According to Thomas, “Sales reports for machine vision components and systems in North America increased 19 percent year-over-year to $709 million in the first quarter of 2018.”

The rise in sales is understandable. The process, in which sensors or a vision-inspection system make real-time registration corrections, can help in a myriad of ways. But too many converters buy them because someone sold them on what the system can do, whether it was needed or not.

To help you determine if a system is the right fit for you, let’s review some of the top benefits for a closed-loop vision system.

Why You Need a Closed-Loop Vision System

As a product is converted, the progression, or the repeat, can experience all kinds of issues that can cause variation in the run.

Joel Oakes, Delta ModTech

Joel Oakes, Delta ModTech

Joel Oakes of Delta ModTech pointed out a number of issues that affect registration, including:

- Debris on the substrates

- Static

- Variable tensions

- Web thickness (varying material properties)

- Coefficient friction of rollers

The list goes on. These items have long been the bane of converters, and traditionally they’ve been corrected after the run. The operator will scout out the errors, the machine will be adjusted, and the process will begin anew.

If the line speed isn’t too blazing fast (even though we want it to be), an experienced operator may be able to make adjustments to the machine during the run. We’ve seen operators manually adjusting the machine via our software, for example.

These approaches are fraught with inefficiencies, included wasted materials and downtime spent waiting for post-run inspections. And more often than not, human error causes a setback.

The Benefits of a Closed-Loop Vision System

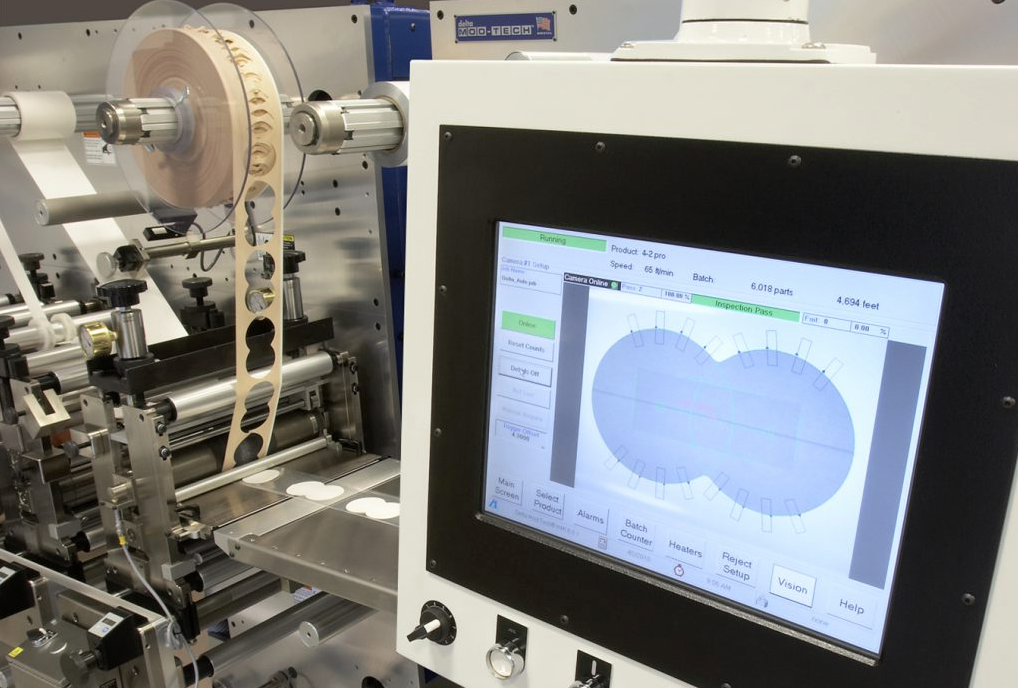

Enter the closed-loop vision system, which uses cameras or cameras and sensors with servo motor control to make registration an automated process. Everything moves faster as the machine makes the corrections, on the fly. The upside can be enormous. Benefits include:

1. Inspection data / traceability reports can verify quality

Product quality can now be verified by providing a software-generated electronic file, as opposed to the old method of statistical sampling. “You get 100% quality verification of each and every part,” Oakes said.

This is critical when you’re required by the FDA or some other regulatory agency to verify your product quality.

2. Real-time feedback

We’ve mentioned the manual inspection process, which requires verifying the quality at the end of a run or given patch. That methodology increases your scrap rate, and eats up labor costs, especially if a product has to be hand-sorted and discarded in the event of a flaw.

3. Reduces the need for offline inspections

Resources are scarce, and quality control personnel might not be as plentiful as you wish. So your operators may have to wait for a final inspection, especially if a company is busy. That means a strain on the quality control resources, and a waste of time for your operators.

4. Limits the chance of human error

The less variables in a process, the better. If you’re relying on the operator to make those corrections, there is likely going to be inconsistency if you have different quality control personnel across the board.

On a more basic level, your operator might just be having a bad day, and suddenly you have a whole batch that needs to be scrapped. Sure, no closed-loop vision system is perfect. It’s just significantly more perfect.

5. Improves staffing resources

So what happens when your key inspection personnel don’t have to focus on inspection all the time? They are free to focus on other areas of your organization. This reduces the stress level on your operators, leading to improved working conditions and increased employee retention.

Sounds Great, but When is a Closed-Loop Vision System Not Such a Good Idea?

Sounds like a closed-loop vision system is for everyone, right? Not always. It may not be the right fit for you.

You’re trying to retrofit an old machine with this new technology. It’s an option, but it may actually result in more long-term costs than if you upgraded to a new machine.

Your operators aren’t open to learning something new. Using the closed-loop vision system will require teaching some old dogs a new trick. You’ll need to devote training time to make it happen, and your team will need to adapt to the new process.

It’s not cost effective. Sure, all the options listed above sound (and are) great, but what if the job doesn’t require a closed-loop vision system. You have to consider the big picture costs before you proceed.

No matter what a closed-loop vision system can do, the benefits always need to be balanced with the reality of the situation. Implementing a system will require financial and operational resources, and a commitment from management.

We love to sell machine vision inspection systems, but only if it’s the right fit for a client. In a world of tight tolerances, we all need to also focus on the margins that pay for these machines at the end of the day: Profit margins. And the only profits that truly matter are yours.

OVERCOME YOUR BIGGEST CONVERTING AND PACKAGING CHALLENGES

Published on Jun 25 2018

Categories: Delta ModTech Blog, Vision Inspection

Previous Post

Choosing Right: Laser Die Cutting Vs. Rotary Die Cutting