Tapemark Dramatically Improves Throughput Through Collaborative Innovation with Delta ModTech

Challenge

Tapemark is a full-service, contract development organization that specializes in the innovation of transdermal, oral thin film, and unit dose, semi-solid drug delivery. They focus on delivering complex solutions to the Rx industry.

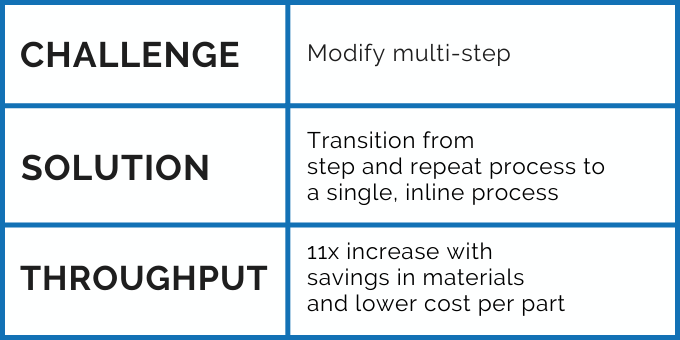

Tapemark had been contracted to produce a medical device product for a customer who currently had a low volume process with multiple steps and step and repeat processes. This involved creating an initial PETG product, and then assembling it with other components that included mesh, foam and adhesives laminations, all of which needed to meet tight tolerances.

Steven Rau is the Senior Director of R&D Engineering at Tapemark, and his team had delivered on the initial feasibility rotary lamination solution for the customer. But now, the customer wanted to hone in on efficiency and volume: How could Tapemark drive costs down, yet improve throughput volume?

Want to see your business’s success story featured on our website?

Solution

Through different feasibility trials on existing systems, the engineering team provided a potential path forward for a robust commercial process.

“The mesh and adhesive materials were very touchy, and could be easily influenced in terms of making it a good part or a bad part.”

Rau and his team turned to Delta ModTech engineering team for help in streamlining the process, working with the easily-influenced materials and tight tolerances, but not impacting quality.

Delta ModTech’s solution was to consolidate a step and repeat process within an in-line process. By adding a custom-designed module to Tapemark’s ModTech machine, they were able to continuously form and die cut the PETG, but then gently place it on a web below that included the sensitive materials.

STEVEN RAU, Tapemark

“The missing piece was that module that allowed us to use a rotary process on a single moving web, which led to a huge increase in volume.”

Throughput

By transitioning to a multiple up and rotary motion, part production increased 11x in parts per minute. Tapemark was able to deliver the client a lower cost per part. “It was a drastic increase in volume capacity and savings on materials,” Rau said.

The results came as no surprise to Rau, who says he’s challenged the Delta ModTech team in the past, “But they’ve never been stumped.”

Beside delivering on the converting solution, Rau also pointed out several key intangibles that add to the Tapemark-Delta ModTech partnership, including:

Modification is the first option. Delta ModTech will look at modifying a machine rather than just selling a new one. “In the end it’s better for me if we can modify an existing machine and up the utilization,” Rau said.

The service team response is fast. If there is a service issue, they’ll quickly send a technician or engineer. Delta has also done remote service over the Internet to get the machines up and running.

“Delta ModTech’s team is fast on a response, and they understand the impact if a line is down.”

The training makes operators more efficient. Delta ModTech’s team has trained operators and engineers in the Tapemark facility, which Rau says helped the operators make the connection between the machine they’re operating and the process they’re running.

“It’s improved the operators’ journey by leaps and bounds and helped them learn the machine and become more efficient on it.”

Ultimately, he values the fact that Delta ModTech is open to suggestions and that some of the feedback his team has made in the past have surfaced on new machines and software.

“They’re listening to the customers on the machines – and they’ll ask how we can do things better,” Rau said. “We’ve then seen our suggestions on newer machines.”

That kind of attentiveness can make a company 11x better — just ask Tapemark.

OVERCOME YOUR BIGGEST CONVERTING AND PACKAGING CHALLENGES

Let’s get started!

Previous Post

Foam Expo North America 2022