Marking and Coding: The Holistic Approach in the Rx World

Serialization. Depending on when you read this, the DSCSA regulations are either coming within a week or they’ve already passed. And yet here we are in December of 2018, and AmerisourceBergen, Cardinal, and McKesson are still reporting an aggregated 60% of their warehouse being coded incorrectly. Still. Now. With the deadline closer than Christmas. How can that be?

It can be, because in a mad scramble to be compliant, one of the easiest things to overlook is the printer. Pull that old embosser or roller coder out, push that continuous inkjet printer down the line to print helper codes, and put your new laser in place and let it rip.

Well, that doesn’t work.

You need to start thinking holistically about your code. The code you are printing now is literally the difference between your company selling product and not. On 11/27/2018, DSCSA regulations stipulate that poor codes aren’t going to be accepted any longer. What the ramifications can be are anybody’s guess, but here you are reading this blog with bad codes and you don’t know why.

I do.

You assumed marking and coding was easy. It isn’t.

Think holistically about marking and coding

Let’s think holistically for a minute. Here are all the different things you may have missed that could be giving you poor codes.

- Substrate

- Material Handling

- Post-print processes

The easiest mistake to make is to pull out the old printer you have and drop your new one in place and assume you’re going to be okay. The precision required to mark the data you are now printing can be greatly affected by vibration.

If you don’t have a laser friendly substrate, or a code box for your datamatrix, your camera is going to struggle to read your barcode. If you have a roller coming into contact with your inkjet printed code immediately after you print it – it can (and will) smear.

Your production line may be working against you every single step of the way if you allow it to, but the most common refrain is always “the printer isn’t working.” Here’s a secret, my friends. Printers are very dumb pieces of equipment in that they do EXACTLY what you tell it to do. You must stop telling it to do the wrong thing.

The good news is, these are easy fixes. But they require collaboration with your marking and coding provider and in most cases your OEM for your host machines and your substrate producers.

Collaborating with your marking and coding provider

You should be sampling your substrate as much as you can to make sure the codes grade the way you want.

We know EXACTLY how to make a laser friendly carton – your provider should too. Ask them if they are providing a laser friendly carton. Remind them to include the mineral layer so that the laser has something to react with. Then look at your package.

Do you have a nice black or dark blue code box that your laser can mark, or has someone in marketing asked for a different color – or no color at all? Is your Datalase laid down consistently, or are parts of it fading?

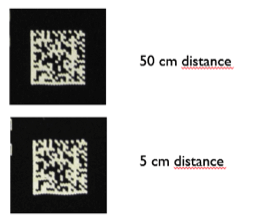

Now look at your production line. Is there vibration (hint, there always is). How close to the epicenter of the vibration are we trying to print?

Just by moving a few centimeters away from the source of the vibration can bring your codes from Ds up to Cs and then Bs. Is there a bar, roller or clamp on your line that’s bowing your carton? Is your label drifting left and right on your labeler? Is your web flexing when it advances? All things that can impact your code.

After you print that code, are you going to put your labeled bottles through a shrink tunnel? Did you use a wax/resin ribbon to print your code? Because that wax and resin can re-melt, then adhere to your shrink wrap, and ultimately come off with the shrink when the plastic is removed.

Are you printing with ink and do you have a carton closer coming into contact with ink before it has time to setup and dry?

It may be the process, not the printer, that’s not working

These are all things I have seen multiple times over. And they all started with a complaint that “the printer wasn’t working.” But the printer was working fine.

What we forgot to do was think about the entire process.

We forgot to think holistically.

But we can fix this, and it doesn’t take a tremendous amount of time – but it does take open dialogue with the other owners of the process – your substrate providers, your OEM partners, and your marking and coding partners. Without them all working in tandem the whole process is at risk.

We can do this. We just need to do it together – holistically.

Paul Hammond is the Sector Manager – Life Sciences with Domino North America. You can reach him at (224) 545-2165 or by email.

Choose the right methodology for your next coating project.