Laser Die Cutting Machines

Increase your die cut capabilities with a laser cutting machine.

We’ve been integrating lasers into our converting systems for over 15 years. We know the advantages of converting with laser die-cutting machines and we’ve seen our customers thrive on the increased capabilities it offers. Now it’s time for you to consider using laser die cutting and giving your company an edge over the competition.

Learn more about EDGE® Laser Technology

Need more information? Contact us today and we can set up a confidential meeting to discuss your project.

Less Downtime

- Verify cut tests immediately.

- Change cut profile or pattern on the fly without stopping.

- No waiting on new dies, No sharpening, No die tooling storage.

- No wear on cutting tools – cut pattern and depth of cut stay consistent over time.

Increase Capability

- Easily cut small intricate sizes and shapes.

- No contact with material during cuts

- Easy slug removal setup

- Cut and seal in one pass

- Laser cutting compliments jobs that require tight tolerance cutting, registration, vision inspection and alignment.

Quicker Time to Market

- Upload a drawing to the HMI and start cutting.

- Product recipes and programs are easily saved and recalled.

- Multiple cuts can be overlaid to minimize amount of material removed during one cut pattern.

- The laser power, process speed, frequency and duty cycle are programmable, allowing the laser to be programmed to maximize speed and quality of cut.

Product Development

Our in-house laser testing lab gives you the ability to have your products tested on various types of laser cutting technologies. Our laser cutting experts will evaluate your materials and cutting requirements to determine which laser options will best fit your needs.

Types Of Laser Die Cuts

- Ablation

- Kiss cutting

- Drilling

- Slitting

- Perforation

- Through cuts and slug removal

- Scoring

- Reject marking

- Scribing & sequential numbering

Materials That Can Be Laser Cut

- PSA, Polyester, paper, abrasives, cork, foam, rubber, neoprene, silicone, PU, PE, PET, polycarbonate, polyethylene, polypropylene

- thin foil, metal

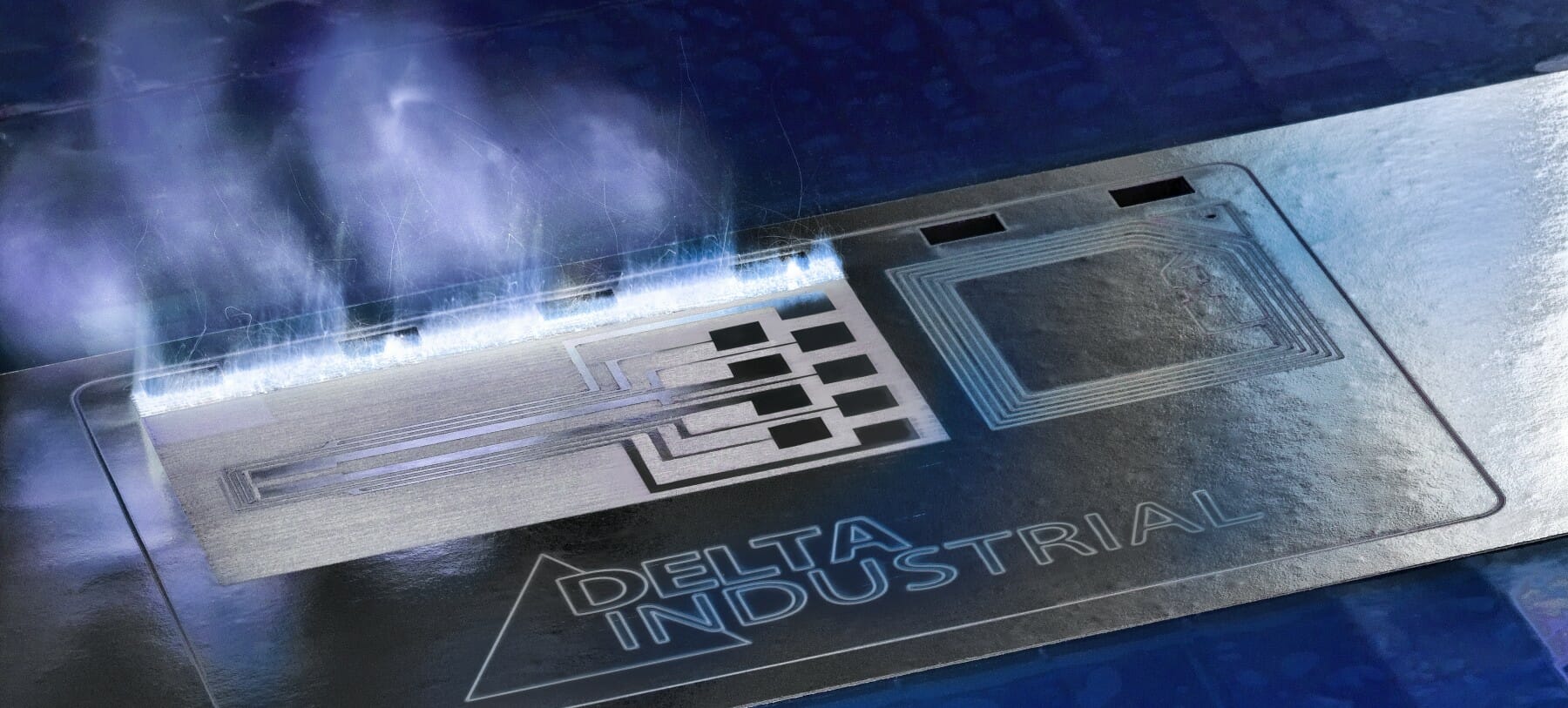

- Ablation of metals bonded to polyester or similar substrates

- Abrasives, adhesives, fabric, paper, plastic, rubber, textiles

Laser Die Cutting Options

EDGE® Laser Converter

The Edge is the perfect solution for markets that demand flexibility. This offering combines our Crusader® rotary converting platform with an Edge laser module. The laser module is servo controlled and can be moved to various locations on the machine with the touch of a button. Need to run a conventional converting process? The edge laser can move up and out of the way giving your team access to 7 rotary stations, web path options are infinite.

Flex EDGE® Laser Converter

The Flex Edge is a flexible laser platform that can be used inline or offline with various configurations to allow for production and R&D use in both roll to roll and sheet-fed. This machine is completely portable. It can be bolted inline directly to an existing Delta ModTech machine, use its telescoping arm to connect to an open station on an existing converting line or run as a standalone unit.

EDGE® Custom – CO2, Fiber, UV/IR

If you want more, we can do it. We’ve delivered some of the most advanced laser converting systems in production today for the most demanding markets. Cutting, ablating, rejecting? Single, dual, even 18 lasers on a single system? It’s been done and we saw it to completion. No matter your requirements, we have a solution to manufacture your product and we aren’t done until you’re making good parts.

Edge® Laser Technology Technical Specifications

| Laser Delivery: | Galvanometer |

| Max Speed: | 91 m/min (300 ft/min) |

| Cut Tolerance: | Application dependent |

| Max Web Width: | 500mm |

CO2

| Power: | 100, 200, 300, 400, 500, 600, 1000, 2500 Watts |

| Wavelengths: | 9.4, 10.2, and 10.6 |

| FOV (Field of View): | 100 mm – 500 mm |

Pulsed Fiber Laser/ Ultrashort Pulsed Laser

| Power: | 10-2000 watts |

| Wavelengths: | 157 nm, 193 nm, 248 nm, 308 nm, 351 nm, 1030 nm, 1060 nm |

| FOV (Field of View): | 100 mm – 500 mm |

From curious questions to preparing a quote, we’re ready to help.

Whether we’re answering some introductory questions or if you’re in need of a quote, just fill in the form or call us at 1-800-279-3358 and we can get you the answers you need.