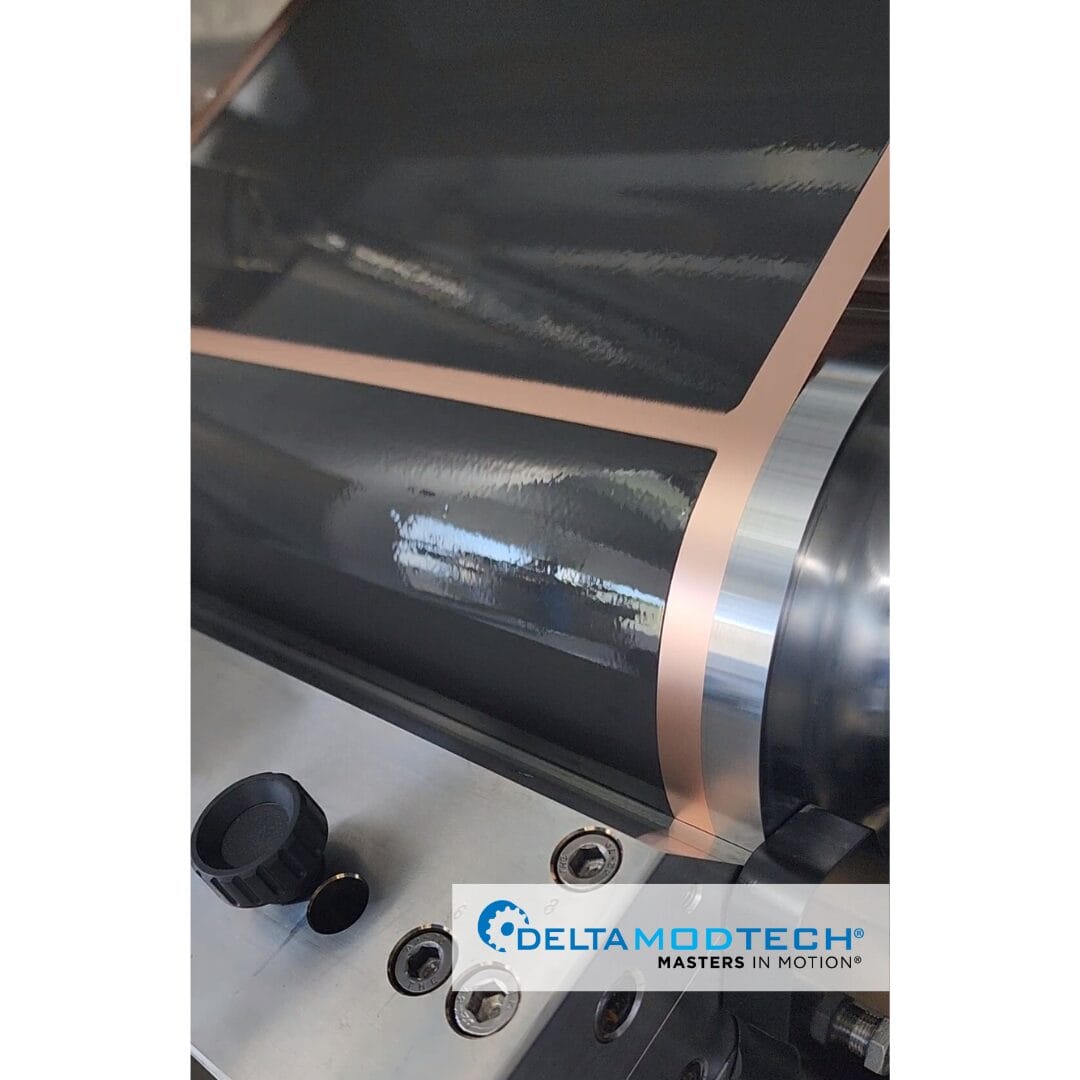

Demo Machine #13: High-Precision Battery Electrode Cutting – Crusader with IR Edge Laser

Battery electrodes need clean, precise cuts to ensure efficient energy transfer and long-term durability

Challenge

Manufacturers often struggle to cut thin aluminum foils without distortion. Conventional rotary die-cutting often causes edge defects, material deformation, and inconsistent cuts. This leads to reduced battery efficiency and increased scrap rates.

Solution

The Crusader® Converter with IR Edge Laser offers high-precision laser cutting for battery electrodes. This system uses infrared laser technology, specifically designed for cutting thin foils with unmatched accuracy.

Features:

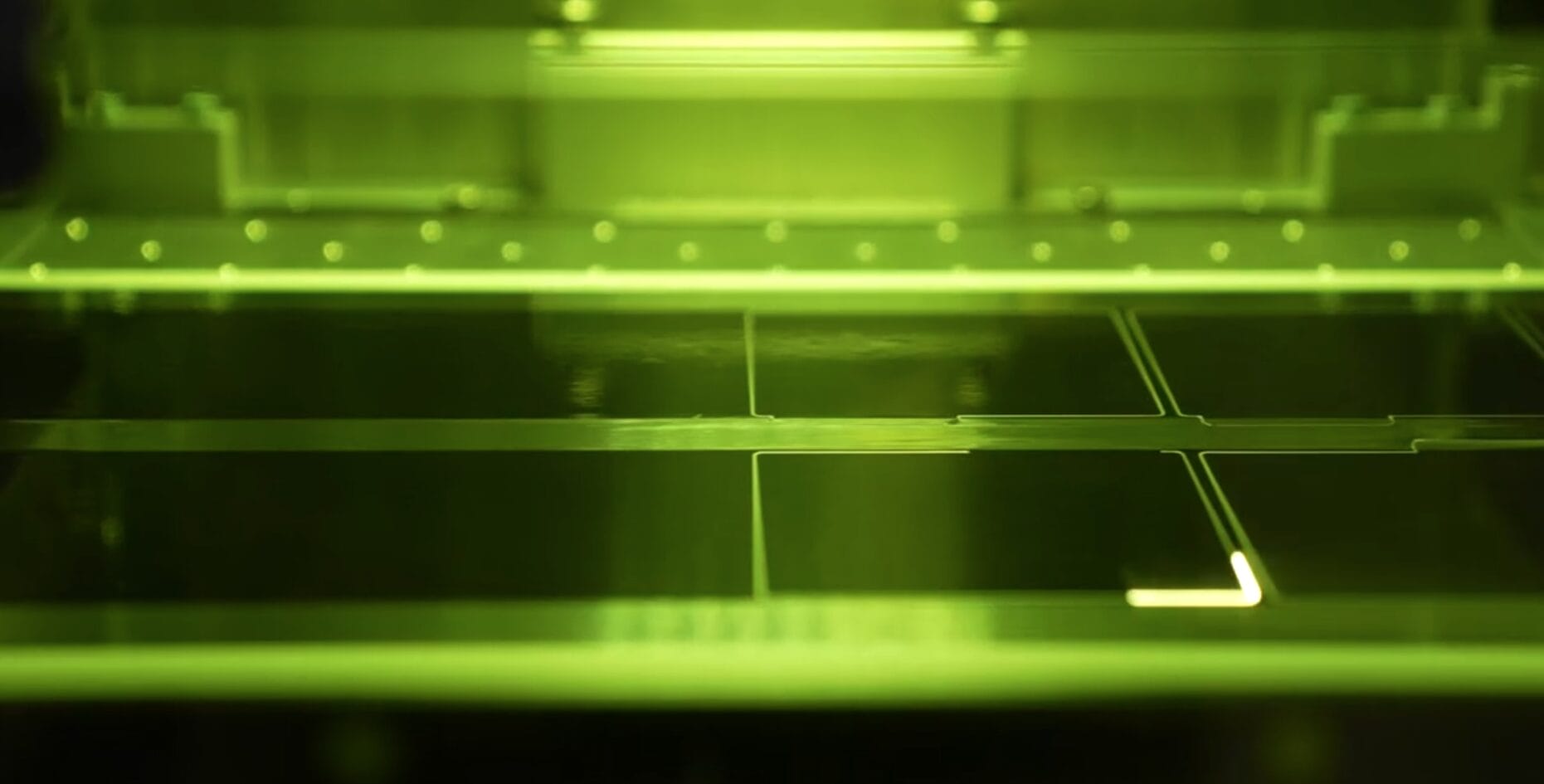

- Unlike rotary die cutting, the IR laser creates smooth, burr-free edges, eliminating material tapering and deformation while improving yield and battery performance

- In-line lamination separator paper is laminated onto the electrode sheet, preparing it for stacking in the next stage of battery assembly

By combining high-precision laser cutting, material handling, and in-line lamination, this solution delivers superior edge quality, repeatable accuracy, and higher manufacturing efficiency.

Note: This material was coated in Demo 9. These demonstrations show

a seamless transition from coating to cutting in battery manufacturing.

Laser Die Cut Electrode

In this demo, the material coated in Demo 9 has been placed on our Crusader® Converter with an IR Laser. Which is then laser cut to and prepared for stacking.

From curious questions to preparing a quote, we’re ready to help.

Whether we’re answering introductory questions or if you’re in need of a quote, just fill out the form or call us at 1-800-279-3358 and we can get you the answers you need.