7 Ways to Reduce Your Converting Costs with Quicker Changeover

Every second counts in manufacturing—especially during changeovers.

That’s why more converters are embracing Quick Changeover, also known as SMED (Single-Minute Exchange of Dies). This lean method is designed to reduce the time it takes to switch from one product to another—without compromising quality or safety.

Why does that matter? Because in converting and coating environments, delays during changeover don’t just hurt output, they increase waste, reduce responsiveness, and add unnecessary costs to every job.

In this post, we’ll cover a range of Quick Changeover details, including the following (feel free to use the jump links):

Defining Quick Changeover (and SMED)

Why Quick Changeover is essential in today’s manufacturing environment

Quick Changeover techniques: The 7 steps to improve Quick Changeover

Converting and coating tools that speed up changeover

Defining Quick Changeover (and SMED)

What is SMED?

SMED, or Single-Minute Exchange of Dies, is a lean manufacturing method developed to reduce machine changeover time ideally to under 10 minutes. Originally used in stamping operations, SMED helps identify and eliminate waste during equipment setups, making changeovers faster, safer, and more repeatable.

Its structured, step-by-step approach has since been adapted for use in a wide range of industries where frequent changeovers impact productivity and cost—from automotive to medical device manufacturing.

What is Quick Changeover?

Quick Changeover is a lean manufacturing method that reduces the time needed to switch a machine from one job to the next. It builds on SMED principles but applies more broadly across different equipment and production processes, helping manufacturers cut downtime and boost flexibility.

In converting and coating environments, Quick Changeover is essential for responding quickly to new job specs, reducing scrap, and maintaining efficiency.

A classic Quick Changeover example

Think of a Formula 1 pit crew changing tires. How quickly they can get the automobile in and out of the pit can mean the difference between winning and losing. That’s why their process is fast, coordinated, and replicable—exactly what SMED and Quick Changeover strive to achieve.

Watch this video of a 1950 pit crew changeover vs. one from 2013. The 1950 changeover takes 67 seconds. The 2013 changeover takes—well, just watch.

Why Quick Changeover is essential in today’s manufacturing environment

In today’s manufacturing environment, pressures are mounting from all sides. Labor shortages, shrinking order lead times, and customer demand for customization are forcing converters to do more with less. That means shorter runs, more frequent changeovers, and no margin for waste.

In converting environments, every changeover often includes tooling swaps, web path adjustments, and recipe validation. For regulated sectors like medical and pharmaceutical manufacturing, the stakes are even higher: longer setups mean production delays, missed delivery windows, and compliance risks.

Without an optimized changeover process, you’re facing:

- Extended machine downtime

- Higher material waste at startup

- Delayed or partial order fulfillment

Conversely, companies that master changeovers enjoy:

- Higher throughput and better yields

- Greater flexibility to respond to customer needs

- Less dependency on highly skilled labor to execute changeovers

In short, Quick Changeover is the foundation for scalable, flexible manufacturing; and it’s more essential than ever in today’s volatile production landscape.

Changeover delays: What they’re really costing you

Here’s a helpful hypothetical converting example. Let’s say your machine runs 10,000 units per shift, each worth $0.50. A 30-minute delay during each changeover could cost you:

- Thousands of dollars in wasted labor and materials

- Dozens of missed production opportunities

- Lost revenue over time

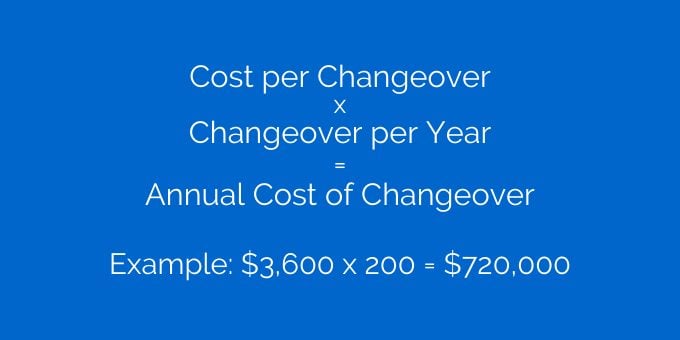

Now calculate the annual cost of a changeover.

Obviously, there’s a lot of money to be saved by improving your Quick Changeover efficiency, but the long-term benefits reach beyond simple dollars.

The real payoff: Benefits of optimizing Quick Changeover (SMED)

If you can attach a dollar value to these improvements, they can help you build a strong case for investing in changeover optimization:

Reduce scrap and improve first-pass quality

Fewer adjustments during setup mean fewer defects—and better quality from the first piece onward.

Lower inventory and free up floor space

Smaller, more efficient batches reduce the need for excess raw material and finished goods storage.

Increase production flexibility

Shorter changeovers enable faster response to changing orders and customer needs.

Improve on-time delivery and reduce lead times

A streamlined process helps you keep promises—and adapt quickly when priorities shift.

Reduce indirect costs

Less material handling, counting, and administrative effort saves time and money.

Simplify training and reduce reliance on operator skill

Standardized processes lower the learning curve and reduce variability across shifts.

More than speed: How Quick Changeover improves agility

While reducing Quick Changeover often leads to improved efficiency, not every manufacturer pursues it solely to boost production capacity. As lean manufacturing expert Tim McMahon explains, reducing changeover can also enable “more frequent changeovers in order to increase production flexibility. Quicker changeovers allow for smaller batch sizes.”

This distinction is especially relevant for contract converters, who frequently switch between a wide variety of short-run jobs for multiple clients. In these cases, the value of Quick Changeover lies in agility—being able to respond quickly to shifting demands without the burden of long setup times.

That said, in industries like medical and pharmaceutical manufacturing—where strict validation protocols and tight production windows are common—reducing the duration of changeovers can be just as critical. In these cases, every saved minute directly impacts throughput, compliance, and delivery timelines.

How to measure your current Quick Changeover time

Start by measuring the time it takes to switch from the last good part of the previous job to the first good part of the next. That’s your baseline—and it’s more than just a stopwatch number.

Video is one of the most effective ways to capture a full changeover. It gives your team a clear, replayable look at the process—helping you uncover inefficiencies and inconsistencies that might otherwise be missed.

In the next section, we’ll break down a 7-step framework to help you reduce downtime, improve consistency, and make steady progress across every shift.

Quick Changeover techniques: The 7 steps to improve Quick Changeover

Now that we’ve defined Quick Changeover and provided a way to calculate its financial impact, let’s walk through a 7-step process to improve your changeover efficiency.

This process is detailed by Ron Pereira of the Gemba Academy. We also recommend listening to this audio interview where he walks through each step.

We’ll apply his framework to a typical converting run so you can see how it works in practice.

Step 1: Observe and document the current process

There are a variety of ways to document your converting machine process. One of the most effective is to video an actual press run. Be sure you’re aligned with union policies and have internal approvals.

You can also conduct one-on-one interviews with operators to uncover variations in how each person approaches the job. If filming isn’t practical, observing the process and taking notes across multiple shifts can still provide valuable insights.

Step 2: Separate internal vs. external changeover tasks

A key principle of SMED is distinguishing between internal and external tasks.

- Internal activities can only be performed when the machine is stopped. For example, changing a rotary die.

- External activities can be done while the machine is running—such as staging materials, retrieving tools, or moving product to storage.

Step 3: Move what you can outside of machine downtime

Are there any internal tasks that could be moved outside of machine downtime?

Examples include:

- Pre-staging materials and tools

- Using dedicated carts for solution-specific pump and coating setups

The more you can move tasks outside of the critical path, the faster your actual changeover becomes.

Step 4: Standardize and improve internal tasks

Next, look closely at the internal tasks that must remain. Is there room for standardization or simplification?

For instance, operators may set die or nip pressures differently. Consider marking optimal settings on the machine or using a chart so all shifts follow the same parameters.

If your die clamps lack pressure readouts, remember that “tight” is subjective. You may need to define consistent torque values—such as turns on a knob—to ensure uniform setup across operators.

Step 5: Optimize tasks performed while the machine is running

External tasks deserve optimization, too. For example, can you store raw material rolls closer to the machine?

You could also create toolkits or job carts that include all necessary items—e.g., rotary dies, sensors, nip rollers, hand tools—ready to go for the next setup.

Step 6: Document everything for speed and repeatability

Once your changeover process is refined, it’s time to document it thoroughly. This creates a foundation for continuous improvement—and ensures you’re covered in case of a system crash or data loss.

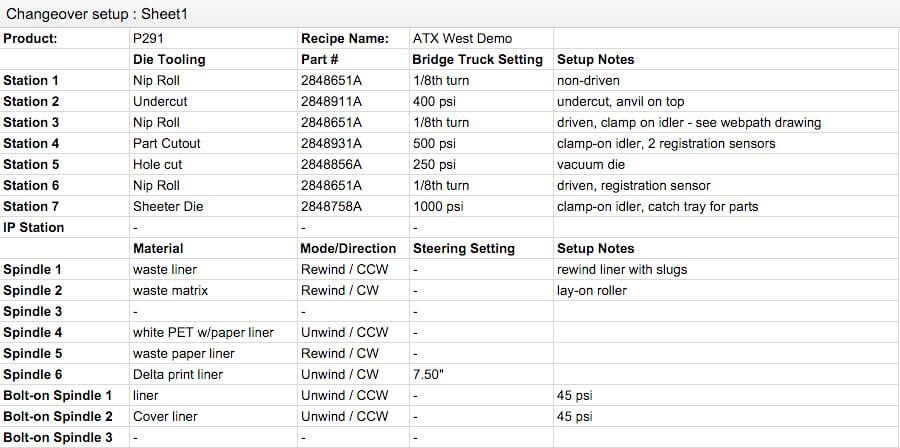

If you’re in the medical or pharmaceutical space, this documentation will also help with regulatory validation. Key components include:

Create a List of Materials

List the materials used for the job, including:

- Specific raw materials (including empty cores for winding waste)

- Where each material is stored

- Required changeover tools: rotary dies, nip rollers, bridge trucks, sensors, hand tools, cranes, etc.

Document a web path for each job

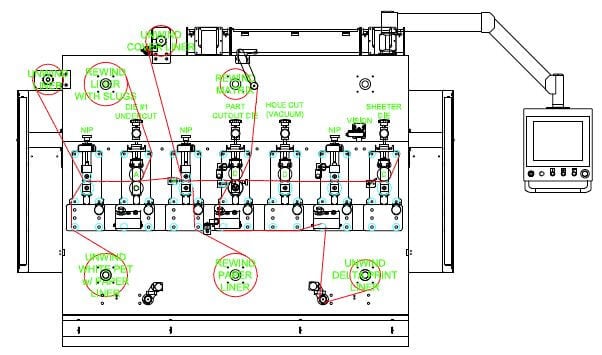

Include all sensor locations, idler positions, clamp-on stations, and web flow. Many clients use a CAD drawing or hand sketch labeled for operators. (We’ve included a CAD drawing example below.)

Document manual adjustments

What settings need to be manually adjusted during the run? Examples include:

- Die/nip pressures

- Hydrojack settings

Because these adjustments can vary by operator strength or body type, document specifics where possible—or automate them when feasible.

We’ve included a list of specific components below that can be manually adjusted on Delta ModTech machines.

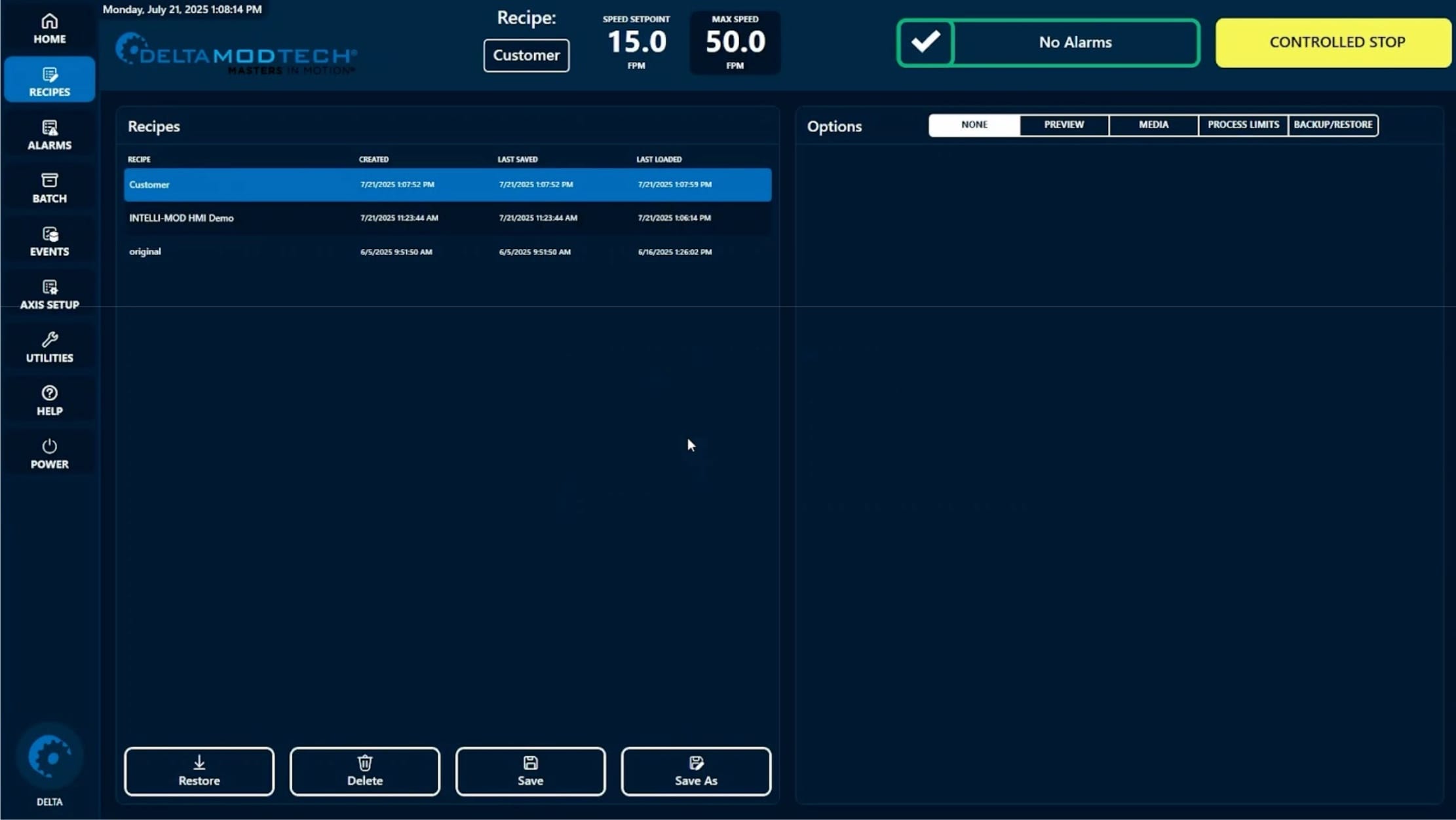

Save the Product Recipe on the HMI

Store each job’s key values in your HMI as a product recipe.

Also, be sure to use consistent naming conventions (e.g., ProductName_partsize_dateofchange).

Keep a List and Label required Die Tooling

Maintain a list of die tooling per job, and label each die with orientation markers. This helps reduce confusion, especially with bi-directional components.

Establish Backups

Once you’ve developed your recipes and procedures, ensure your process data is protected with digital backups:

- Store recipes on a secondary device or network

- Scan web path drawings

- Digitize manual adjustment lists

- Back up tooling lists on a shared drive

Backing up to an offsite server is recommended. You’ll also need to create a regular schedule to maintain updated backups.

Step 7: Make continuous improvement part of your culture

This is just the beginning. With your Quick Changeover process in place, you can now refine it—bit by bit, shift by shift.

Making this part of your operational culture takes commitment. But as Ron points out in the audio interview above, you can see significant results in as little as 1–2 weeks by following this method.

And in manufacturing terms, that’s fast.

If you’re looking for a reliable method to track your downtime and changeover progress, be sure to consider ModTech CONNECT™. This powerful new tool can dramatically improve your data collection and ultimately help transform your long-term performance.

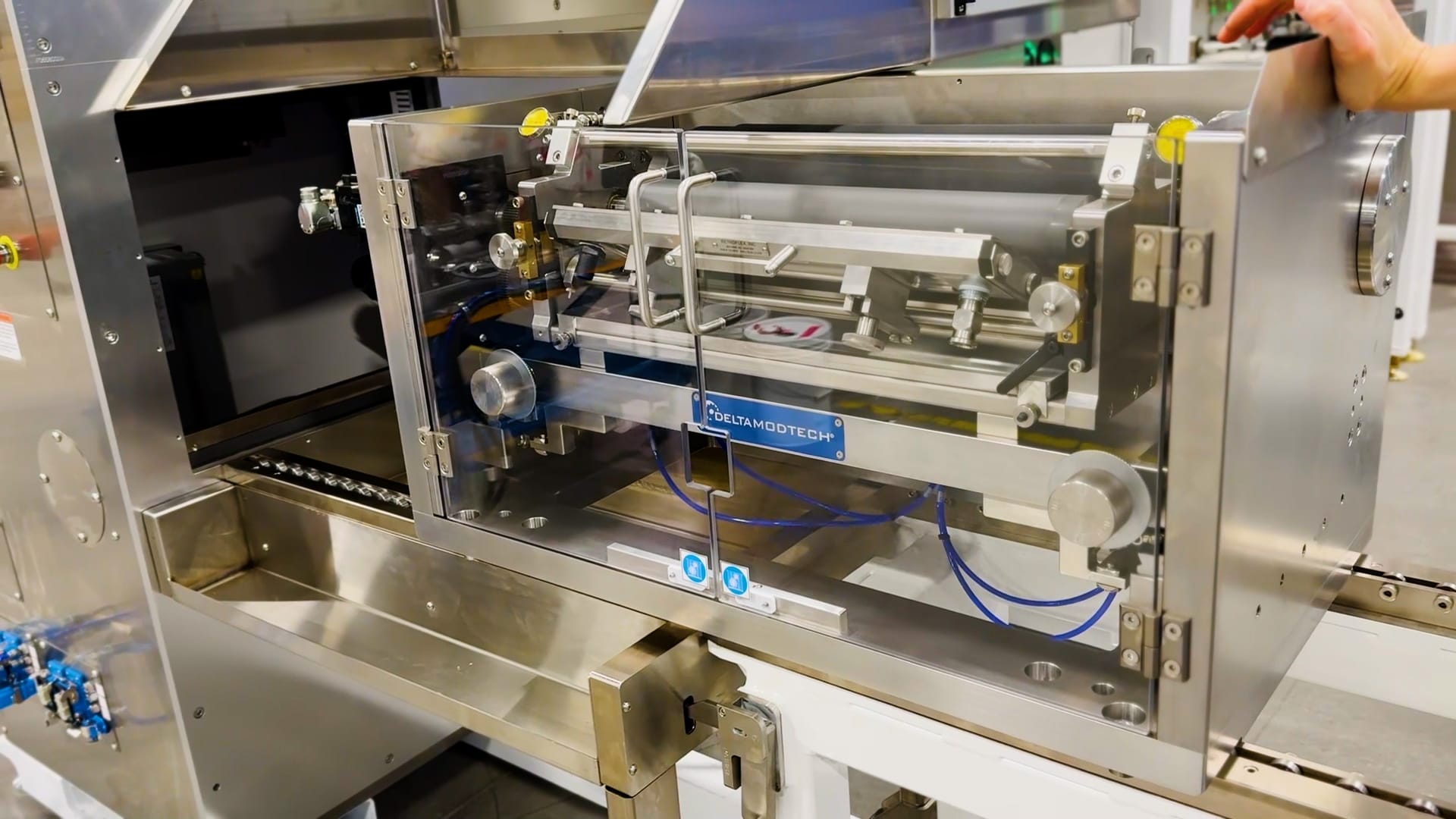

Converting and coating tools that speed up changeover

Delta ModTech has developed a range of modules and enhancements designed to significantly reduce changeover time while improving precision and repeatability. These aren’t just features—they’re practical tools your operators can use every day to get jobs running faster and more consistently.

Converting enhancements:

T-Slot idlers and clamp-on idlers

Idlers are used to change the web angle, and converters love using them because they provide added flexibility based on the project. Instead of clamping individual idlers or manually repositioning hardware, the T-slot idler and its slotted rack allow you to move idlers up/down or left/right within the slot, then lock them into place quickly.

How it helps: Quickly make precise adjustments to the web angle to aid in lamination, de-lamination, tension control, and more.

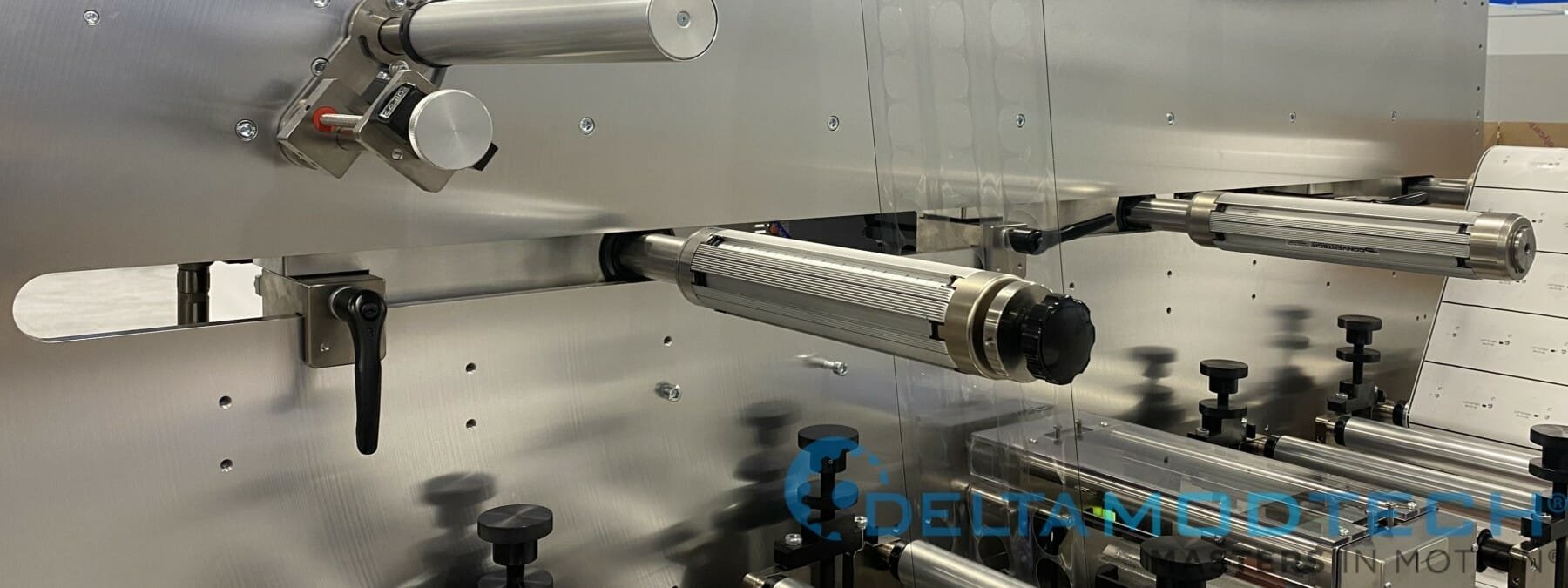

Movable and bolt-on spindles

Everyone wants more spindles on their machines, but fixed spindles can interfere with web paths. Before movable designs, you’d have to mount more idlers to work around these constraints. Now, with movable spindles, you can simply slide them out of the way.

Bolt-on spindles can be added anywhere on the front plate of a Delta ModTech machine. You can use pneumatic spindles for waste matrix rewinding or add a bolt-on servo spindle for unwinding/rewinding with precision tension control.

How it helps: Move spindles quickly to adjust web paths or add winding capacity wherever it’s needed.

Die station cross-web adjustment

Die station tracking allows you to move each station cross-web (operator side to machine side) for fine adjustments.

How it helps: Make small web steering adjustments or shift die cuts laterally by simply turning a knob. Each knob includes a digital readout for accurate movement reference.

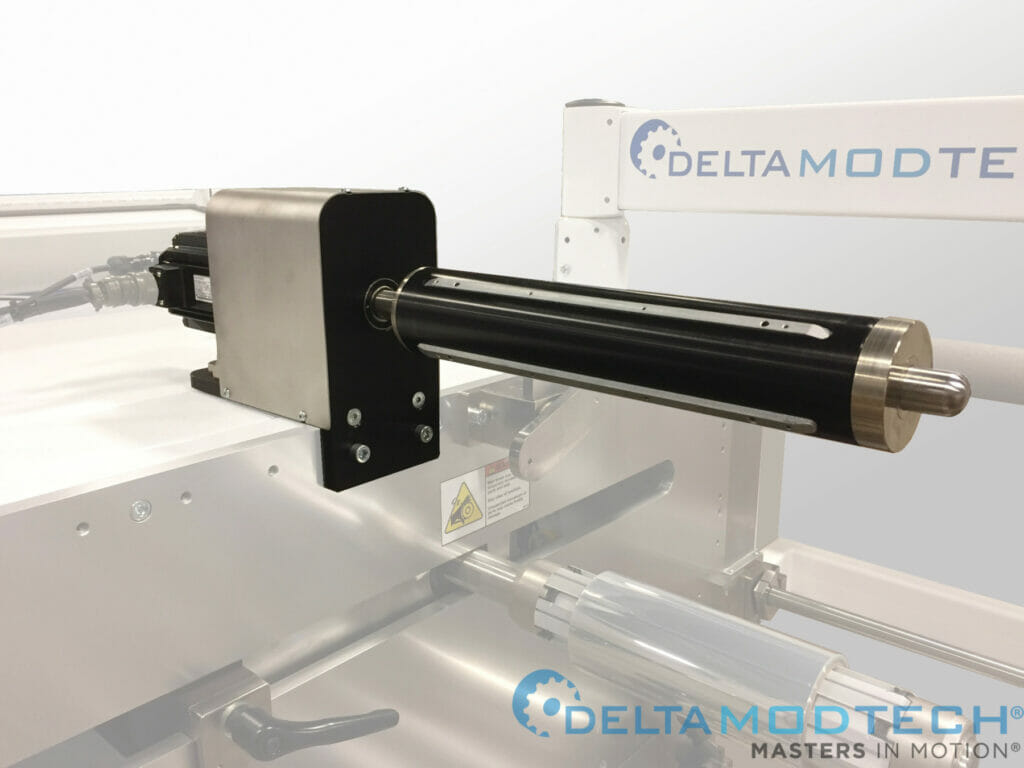

Hydraulic bridge trucks

Operators once relied on two mechanical bridge trucks to apply pressure to die and nip rollers, repeating the process manually and inconsistently during every changeover.

Hydraulic bridge trucks simplify this task by applying uniform pressure across the die with minimal effort. The pressure can be precisely set and documented using the onboard readout. These clamps are particularly effective for metal-to-metal die cuts requiring high force.

How it helps: Simplifies die pressure setup and allows for uniform, repeatable pressure across the roller.

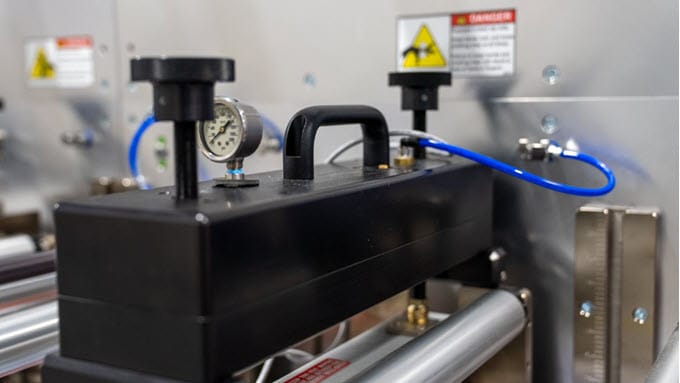

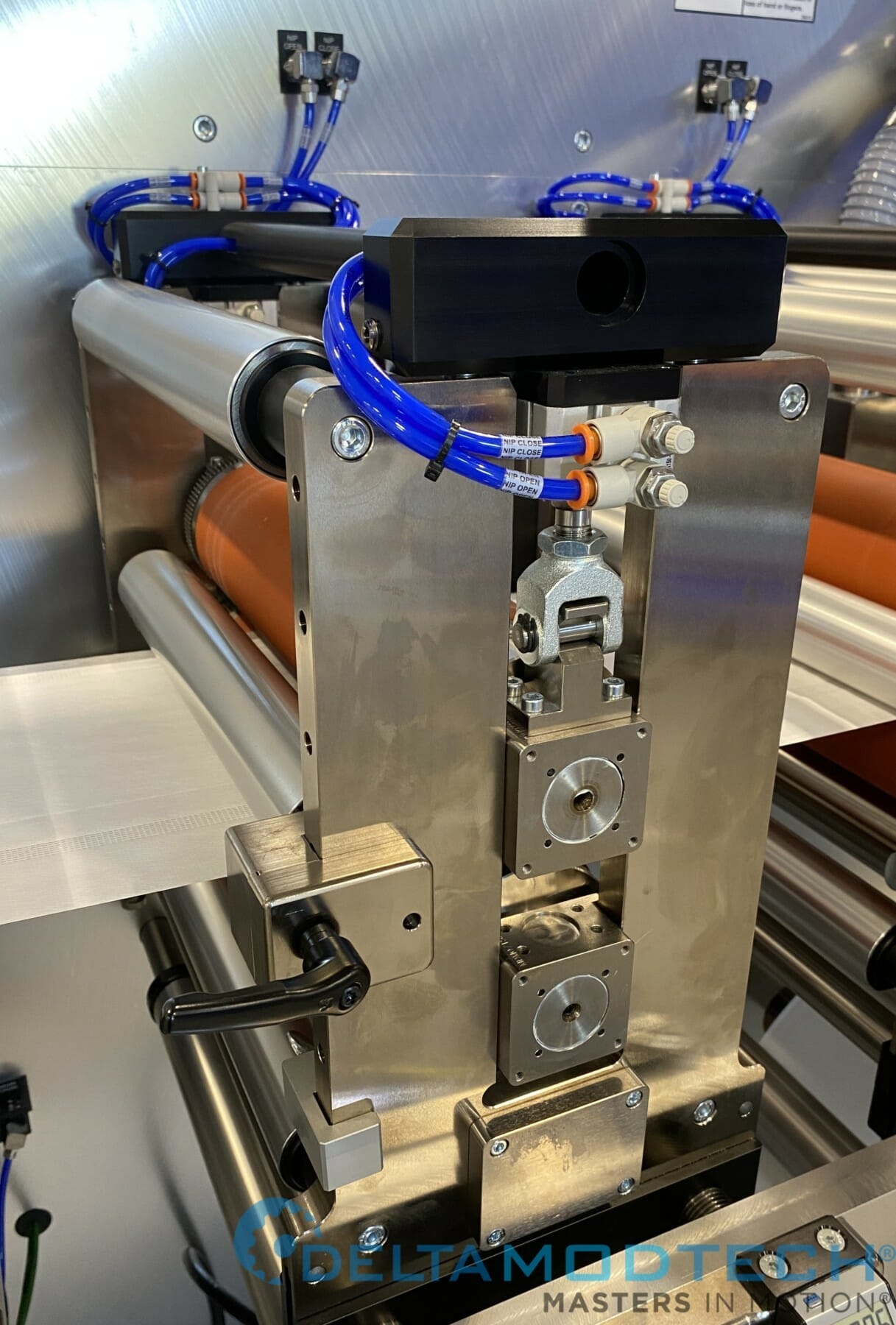

Pneumatic nips

Pneumatic nips automate nip pressure adjustments. Operators can store parameters as part of a recipe, then recall them at the push of a button.

Our pneumatic nip bridge trucks also enable tool-less installation and removal, making it easy to reposition between stations.

How it helps: Instant nip setup with uniform roller pressure, plus fast relocation between stations.

Coating enhancements:

Dedicated pump carts

Pump carts hold fluid compounds and deliver them to the slot die coating station via fluid lines. The carts support pressures up to 50 psi (345 kPa), with onboard sensors to monitor pressure and shut off the pump if it exceeds the safe limit.

How it helps: Speeds up fluid changeovers by eliminating the need to purge and re-prime pumps between jobs.

Displacement tubes

Perfect for short runs, displacement tubes reduce wetted surface area and minimize fluid change time. The system uses glycerin to push coating fluid through the tube in a controlled, metered fashion without filling the entire pump system.

How it helps: Ideal for small batches and fast fluid swaps with minimal cleaning and downtime.

Weight gauge (measurement system)

Based on ultrasound technology, this system measures basis weight online and without contact. The system can use traversing or fixed sensor heads to create a full web profile. It can also calculate coating thickness when material density is known.

How it helps: Provides precise, real-time coating measurement for better process control.

Changeover cart

Used to swap entire coating stations, the changeover cart docks with the machine so the station can slide off safely. A new module can then be brought in and positioned using a second cart.

How it helps: Enables fast, modular swaps of coating stations, which is ideal for high-mix operations.

Electrical dampener

Dampeners in the oven’s air ducting control airflow into top and bottom nozzles. With electronic control via the HMI, operators can precisely adjust conditions during the drying process.

How it helps: Allows for consistent drying conditions across runs, improving repeatability and product quality.

Additional enhancements for coating efficiency

In addition to the tools described above, Delta ModTech systems can incorporate a variety of optional enhancements to further accelerate coating changeovers and improve consistency:

- Additional pump carts and slot dies. Maintain separate pump carts and pre-shimmed slot dies for specific solutions to avoid downtime between formulations.

- Quick-change coating stations. Quickly swap between coating methods—such as slot die, gravure, or comma roll—to accommodate different product requirements without a full teardown.

- Recipe-based dryer configuration. Store and retrieve full dryer zone settings (temperature, blower speed, nozzle position) as part of each product recipe for consistent, repeatable setups.

- Dedicated variable-speed blowers. Use independent supply and exhaust blowers per zone to fine-tune airflow across the drying profile.

- Motorized nozzle height adjustment. Automatically reposition dryer nozzles based on saved parameters for each product type.

- Integrated QC systems. Speed up changeovers with in-line systems that confirm product quality on startup, including:

- Basis weight and thickness gauges

- Vision inspection systems

- Fluid delivery mass flow meters

From waste reducer to growth driver: The strategic power of Quick Changeover

Quick Changeover started as a lean manufacturing concept; but today it’s much more than that. It has become a strategic lever for efficiency, responsiveness, and long-term growth.

For converters working with complex processes, demanding clients, and strict regulations, mastering changeovers can help you:

- Reduce production costs

- Speed up delivery timelines

- Improve quality and consistency

- Simplify training and reduce labor dependencies

And the best part? You don’t have to wait months to see the results. With the right process and tools, many teams see significant improvements in just weeks.

Want a personalized assessment of your changeover opportunities? Contact Delta ModTech today. We’ll analyze your current process and suggest proven upgrades that save time and money.

Published on Aug 22 2025

Last Updated on Aug 25 2025

Categories: Coating, Converting, Delta ModTech Blog, Purchasing